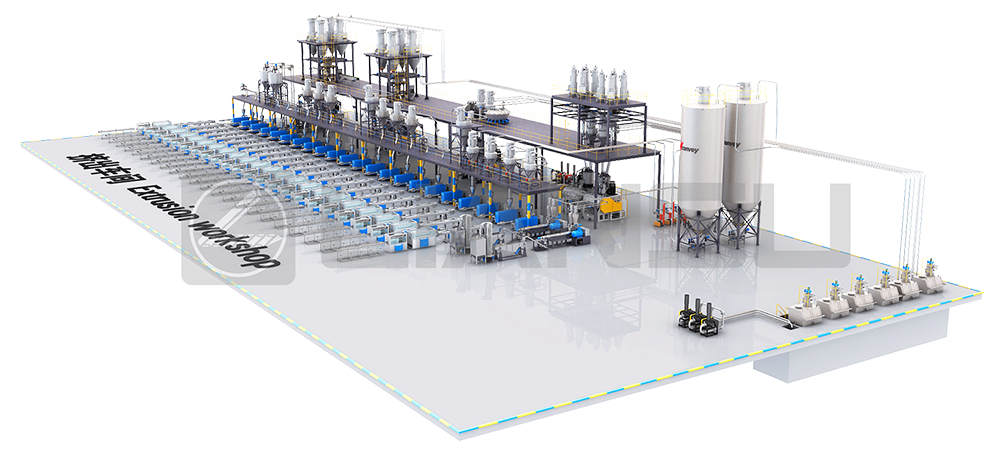

In the plastic extrusion industry, for medium and large-scale pipe, packaging film, board,sheet and other profile products manufacturers, we provide a complete set of customized full-automatic dosing and feeding system scheme from the storage of material, material conveying, weighing and mixing, automatically convey to each extruder for production. The system control integrated with data analysis module to figure out the multi dimensional data collection and analysis of equipment utilization, material consumption, energy consumption, production capacity,equipment maintenance,etc.

Introduction to multi scenario applications

▶Unpacking storage We can customize standard bag automatic unpacking station, ton bag feeding station and 25KG standard bag feeding station according to customer needs.

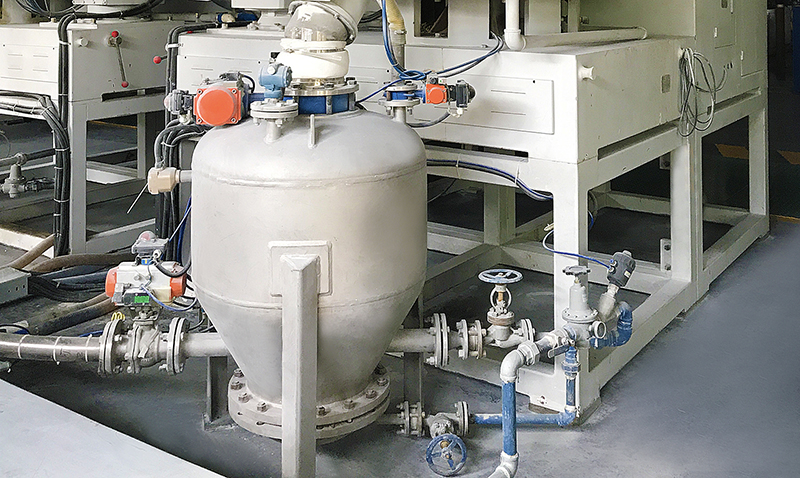

▶The conveying of main material adopts positive pressure dilute phase conveying, negative pressure dilute phase conveying and positive pressure dense phase conveying. Select the best scheme for customers according to the actual situation of the customer.

▶The precision weighing scale adopts high-precision bending beam pressure sensor to ensure accurate weighing.The measuring scale adopts stainless steel or synthetic rubber weighing bin, matched with flow aid air bowl and pneumatic beating mechanism to ensure complete discharge and no accumulation of material.

(According to the formula requirements of customers, a small material formula scale is equipped for the automatic measurement of each component material of additives, and the small material is accurately measured by spiral feeding.)

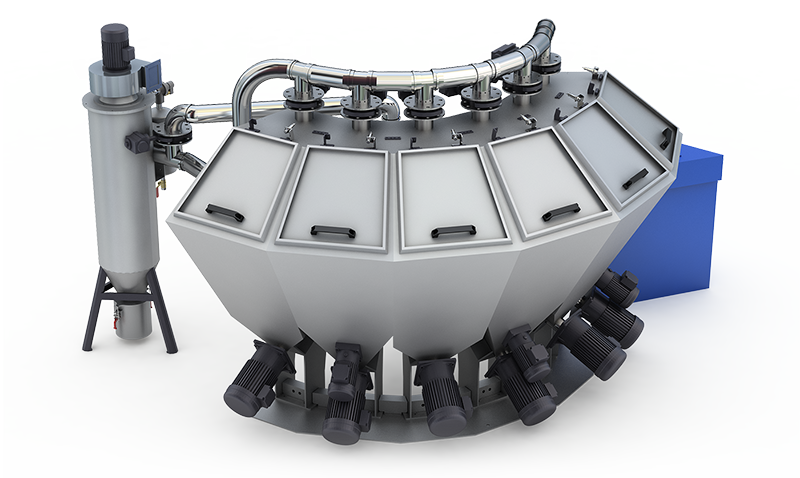

▶The measured main material and auxiliary material are conveyed to the "mixing mechanism" by gravity or "screw conveying".

(GRH1000/LH3000)

(GRH500/LH1500)

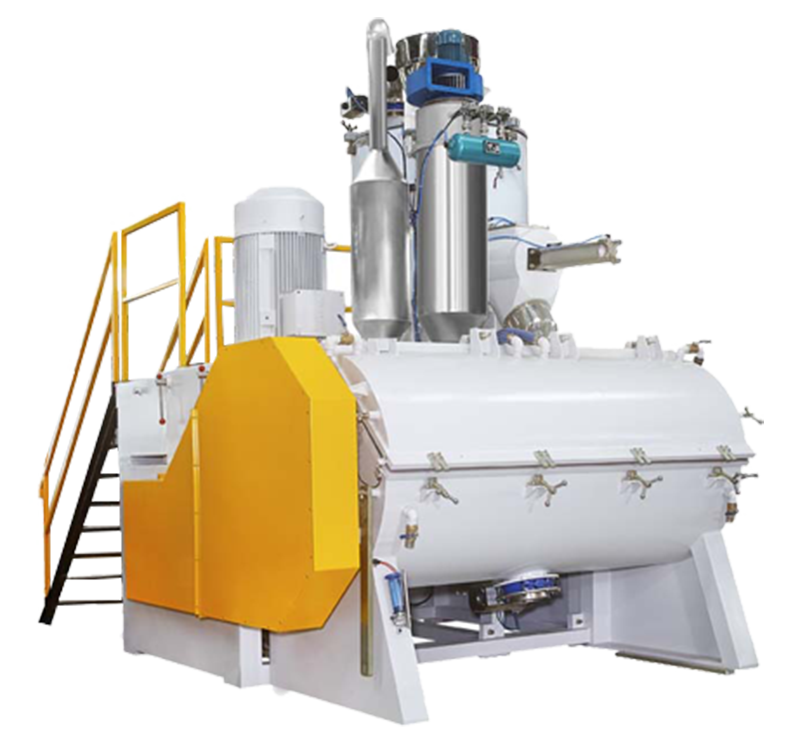

(The high-output and low-energy consumption "high-speed mixing mechanism" independently developed and produced by Liansu has a comprehensive power consumption of 30 ~ 40KWH/T, a comprehensive output of 1.7T/h for the model GRH500/LH1500 mixer and 2.9T/h for the model GRH1000/LH3000 mixer.

•The high-speed mixer adopts high torque, ultra-high efficiency permanent magnet synchronous motor, with high energy-saving rate and high power factor, without the input of additional power factor compensation capacitor cabinet.

•The blade adopts special structure, with strong material blending and rolling effect. The blade surface adopts multi-channel sintering and spraying process, which is wear-resistant and durable)

▶For high-speed dosed material, select "pneumatic conveying" or "mechanical conveying" (pipe chain conveyor or screw conveying) according to the customer's material composition and conveying distance

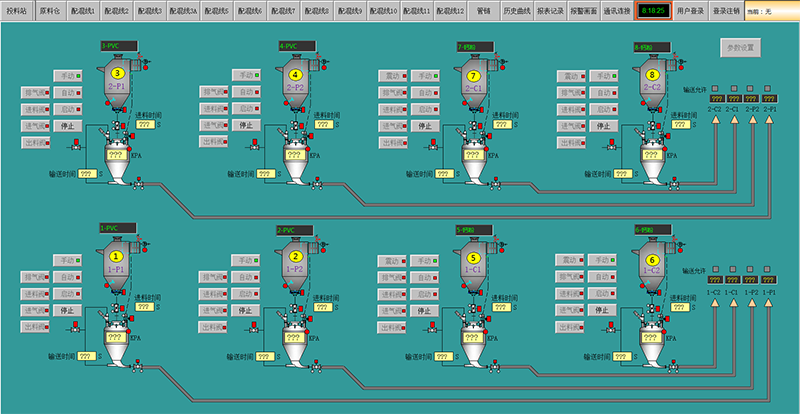

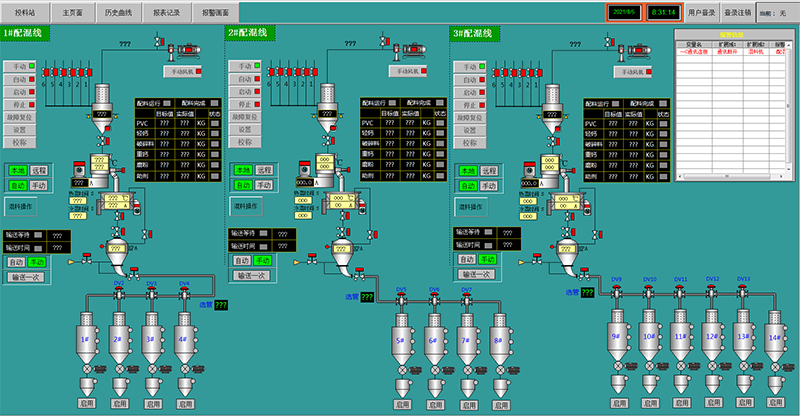

▶The full-automatic control system combining IPC and PLC is adopted, and set up the central control unit which communicates with each component: mixing system, metering system and conveying system. The network communication of "one network to the end" is adopted to fully achieve the central control of each link, realize the whole process automatic control and monitoring, store the formula required for production, and statistics and analysis of production data.

Liansu Machinery integrates 26 years of extrusion equipment manufacturing experience, provides a complete set of upstream and downstream automation system scheme of extrusion equipment, and 100% independently developed integrated control system, familiar with the plastic extrusion process, and match the whole ecological solution of the optimal feeding system, extrusion system, automatic packaging system and production data acquisition and analysis system.

In 8 years, domestic and overseas 56 powder feeding system projects and 102 granule feeding system projects were completed, including the plan making, self-made production, on-site construction, commissioning and acceptance. Realize the transformation of old and new plants, multi formula, multi color, high filling and long-distance conveying system.

Customer site case