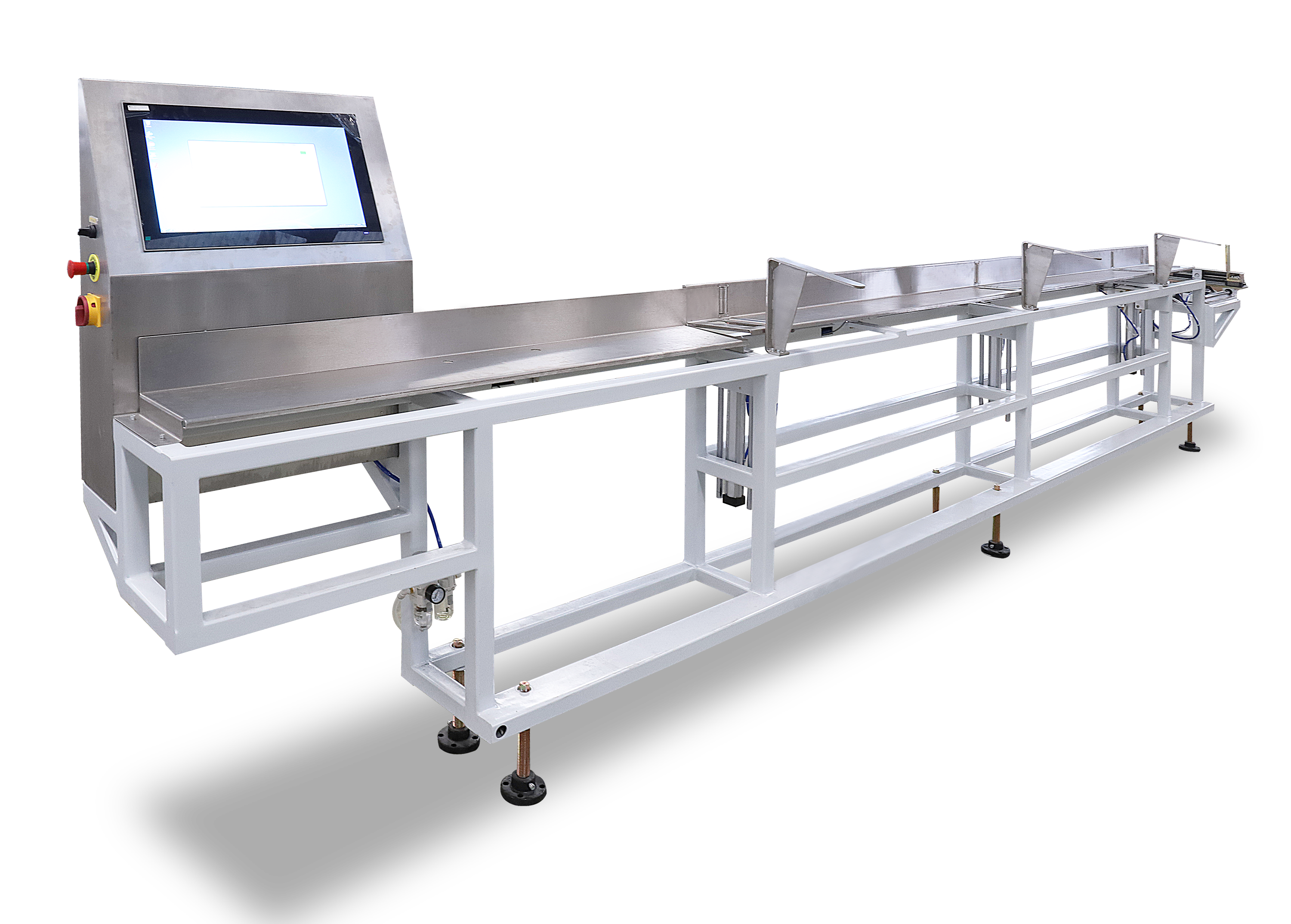

Pipe stacker with auto meter-weighing system

On-line weighing Reduce waste

Integration to control of hual off to adjust pipe thickness

Advantage

➊Body dimension: 6000*667*1260 (L * W * H), compact size .

➋The qualified pipe is automatically lifted and stacked to the material cage after cutting.

➌Online real-time monitoring of the weight of each pipe, and automatically eliminate the unqualified weight of the pipe.

➍Automatically count the qualified and unqualified quantity and weight of pipe

➎Integrates the data of Vacuum close-loop control .

➏Be able to combine with vacuum tank negative pressure data, link with cutting machine, automatically remove the waste products(IPC).

➐It can integrate the energy consumption , extrusion current, torque and other key data of extruder (IPC).

➑Integrating weighing data, vacuum negative pressure automatic adjustment data and the actual running status of extruder, the wall thickness of pipe extrusion can be adjusted in real time, improve the quality of pipe, and save the material.

➒IPC with 17 inch color touch screen is optional to realize data acquisition and data analysis (IPC) of the whole line.