LIANSU provides one-stop high output PVC compound pelletizing solution from material feeding, weighing, dosing, mixing, extrusion, pelletizing to packaging. It realizes accurate material mixing and dosing controlling and process technology monitoring to ensure efficient production and improve product quality. Hereunder we will share our PVC automated compound pelletizing solution to you .

Automated Material Handling System

The feeding system was supplied by Mconvey and covers unpacking, silo, weighing, mixing, dosing, storage and delivery. The system accurately feeds the raw material to the weighing scale through jumbo bag discharging station or feeding station, ensuring accuracy debagging. Then the material enters the high-speed compound mixer for uniform mixing and is stored in the silo and through screw conveyer to convey the material to the production line. This system significantly improves production efficiency, reduces human error, and ensures an efficient and safe production process.

High Output PVC Compound Pelletizing

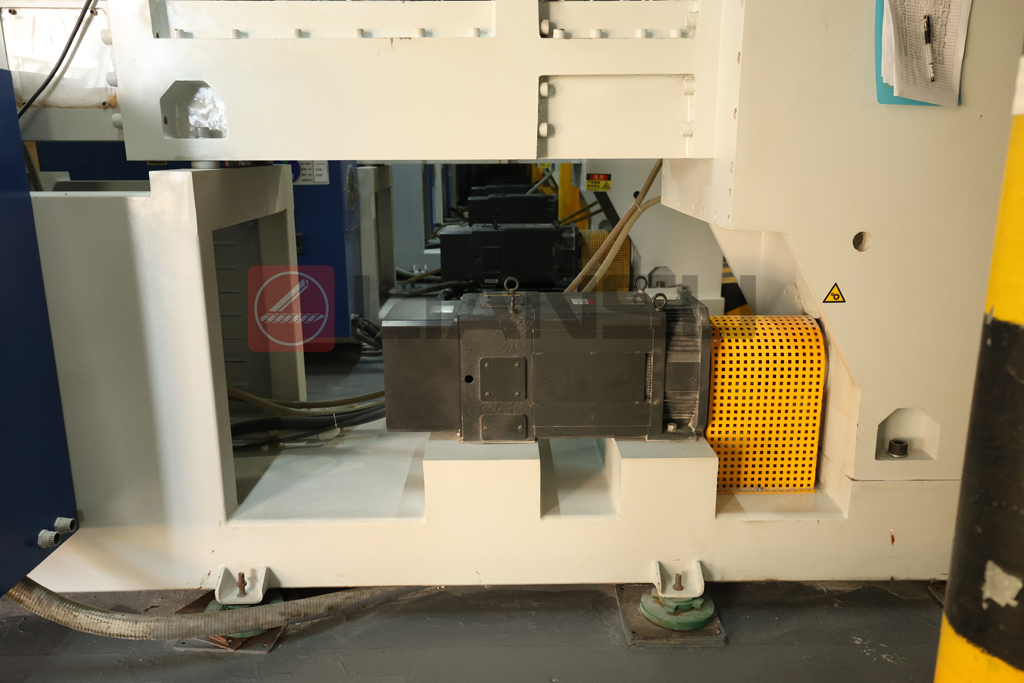

PVC pelletizing line is equipped with high output parallel twin screw extruder, specially designed screws for different PVC compound, even material mixing and plasticizing, especially suitable for handling with high-viscosity, complex formulations of the material to achieve high output and low energy consumption, low noise, no dust, uniform pelletizing. In addition, the extruder can be equipped with on-line loss-in-weight feeder and on-line pigment doser to improve the stability of extrusion and quality control, and can realize flexible on-line color change.

The pelletizing line adopts LlANSU patented design water-cooling system,which is odorless, dust-free and long service life and maintenance-free, and is completely different from the industry's traditional "vibration-type” cooling conveying structure, and the cooling efficiency has been significantly improved.

The whole line can be equipped with automatic jumbo bag packaging machine, automatic online weighing and bagging, much reduce labor work and improving packaging efficiency.