HDPE spiral pipes are widely used in municipal drainage, sewage treatment, rainwater collection and water containers with it's excellent corrosion resistance, pressure resistance and light weight, also widely used in various engineering projects. LlANSU is committed to providing customers with stable and reliable pipe extrusion solutions. Hereunder we will share the latest big diameter range of HDPE spiral pipe extrusion line.

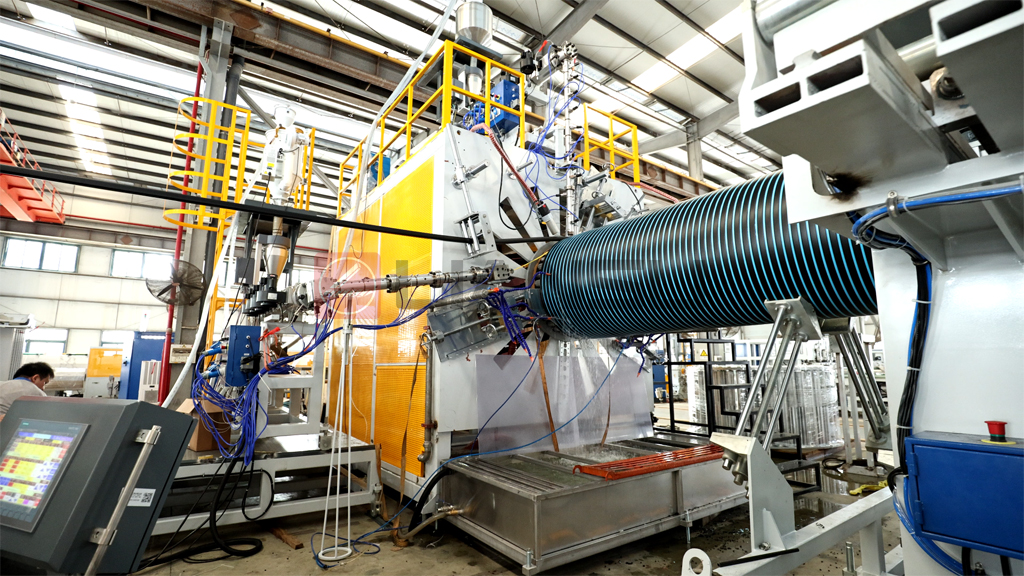

LSWP- 2400PE Spiral Pipe Extrusion Line

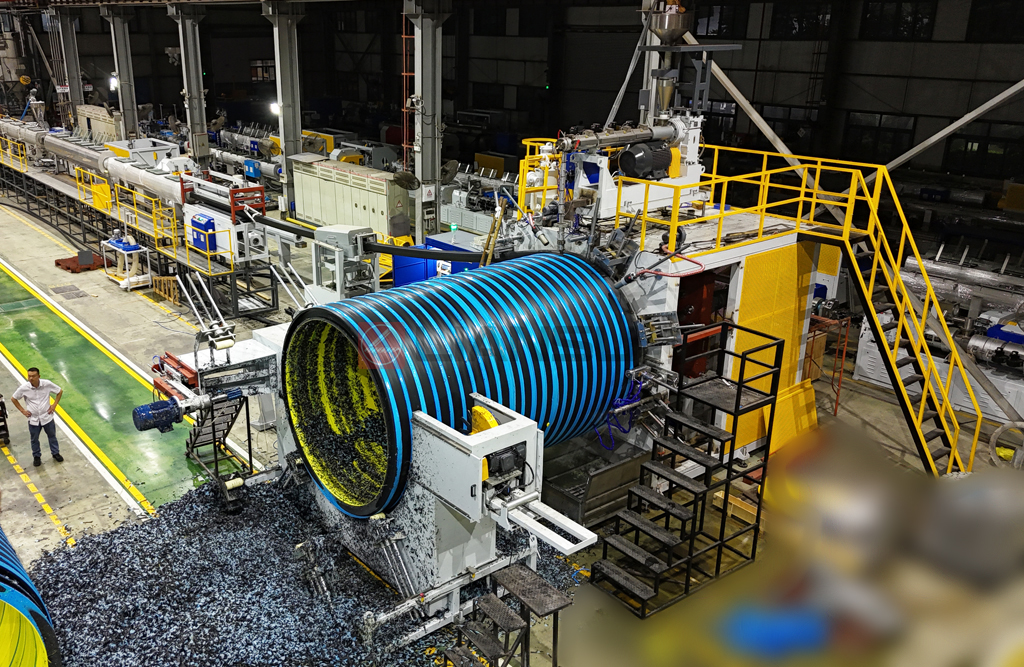

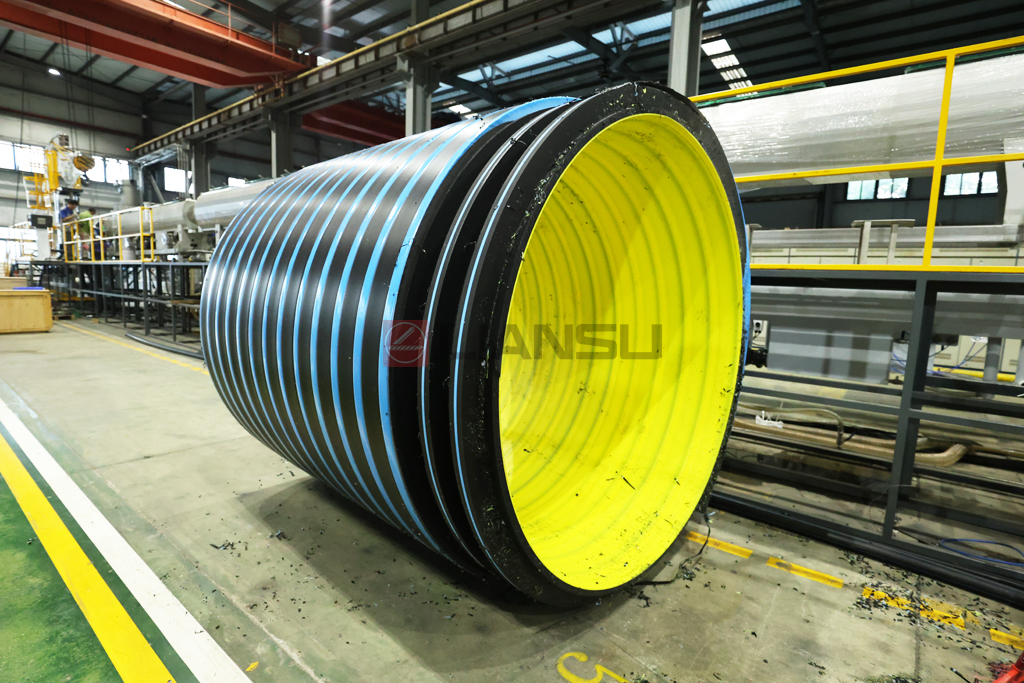

· Pipe diameter: 1000mm-2400mm

· Capacity: 1000kg/h

· Ringstiffness scope: SN4~SN16

· Requirement: Pipe end with external and internal thread cutting

Adopts LIANSU high-performance single-screw extruder to ensure uniform plasticization and high extrusion efficiency. Extruder equips with a precision temperature control system to improve the melt temperature stability and product quality.

Profile pipe head adopts spiral design with a scientific flow channel, supports specification changes.

Vacuum calibrator enables profile forming and rapid cooling, ensured accuracy dimension and production efficiency.

Forming machine ensure profile product efficient forming ,stable synchronous of internal and external co-extrusion technology , realizes the good melt of inner and outer layer materials. the spiral head is connected to the universal joint through a distribution gearbox, with stable transmission and easy replacement.

Saw cutter supports internal and external thread cutting, which is convenient for pipe connection, and precise synchronous control ensures accurate automatic cutting.

The whole line adopts PLC control system to realize synchronous control of the production and provide multi-level alarm functions for intelligent and efficient operation.