In recent years, with the increase in the drinking water and agricultural water supply in part of domestic and overseas markets, the demand for large-diameter HDPE pipeline extrusion equipment in the market has gradually increased. And the delivery volume of Liansu in large-diameter pipeline extrusion production lines in recent years has also accounted for the highest proportion, especially for models LSP-630, LSP-800, LSP-1200, LSP-1600, and LSP-2000 pipeline production lines. The wall thickness of pipes has also increased from the conventional 57mm to the current 135mm, for which the production process technology and equipment requirements for pipes are increasingly high.

How to improve the production stability, qualification rate, and reduce waste of large diameter HDPE pipeline is a technical issue that plastic pipe manufacturers are concerned about. In response to this issue, we will share the technical optimization of Liansu in the extrusion production equipment to help high-quality large-diameter HDPE pipeline production.

Material selection

First of all, the selection of HDPE materials is important, as different grades of HDPE materials have different performance characteristics and need to be chosen based on actual production needs. For example, when producing large-diameter PE pipes, the preferred material is PE100, which has excellent pressure resistance, impact resistance, and corrosion resistance, while also meeting the strength requirements of large-diameter pipes.

However, it is recommended to choose the material with sag resistance for the production of thick-wall pipes. Because the thick-wall pipes are prone to sagging during production, and the HDPE materials with sag resistance can maintain good stability at high temperatures to ensure the pipe quality and strength .

In addition to the above situations, there are other factors. For long-term exposure in outdoor environments, the material should be good weather resistance. And for corrosive media transportation, the material should be good corrosion resistance .

Therefore, it is necessary to select the most suitable material according to the actual production needs. At the same time, pay attention to the processing technology and quality control of materials during the production process to ensure the pipe stable and reliable performance.

Extrusion Equipment performance

In order to meet the specific extrusion process requirements, the performance of extrusion equipment is also important. It mainly include screw design, material melt temperature control, die head design, vacuum control, haul-off speed control, and automated cutting unit.

Extrusion

For the production of large-diameter HDPE pipes, Liansu adopts self-developed 40 L/D ratio extruder, matched with spiral feeding sleeve to ensure high output of the extruder and the plasticization and low melt temperature of the material. For the 800mm pipe or above and the SDR11 product thickness or above, the melt cooler configured at the end of the extruder can reduce the material melt temperature before entering the die head, shorten the cooling length of the tank, and minimize the melt sagging as much as possible to ensure uniform wall thickness.

Die head design

Single or multi-layer die head adopt spiral structure, and equipped with multi spiral flow channel distribution body design, as well as air cooling and oil cooling structures to reduce the residence time of materials in the die head and further stabilize the melt temperature.

Vacuum control

The automated negative pressure closed-loop control system can ensure pipe rapid forming, fast dynamic response, and real-time detection of vacuum leakage and automatic compensation, making vacuum forming more stable. In addition, the automatic adjustment of vacuum pump speed can reduce the noise of vacuum tank and save energy over 50%.

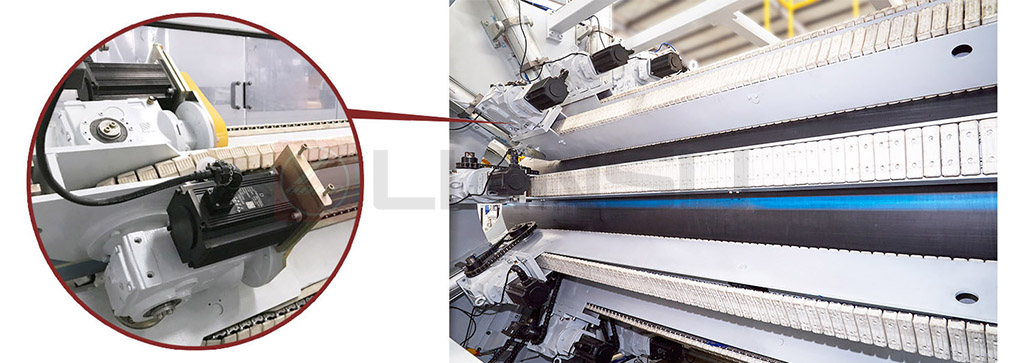

Stable hauling

The haul off unit adopts "one haul multiple" synchronous control mode, which means a single driver drives multiple permanent magnet synchronous servo motors simultaneously with stable low-frequency torque output and wide speed regulation range, making the production process smoother and reducing potential waste. The caterpillar adopts self-expanding copying device to ensure the chain and the track are closely adhered to each other to improve the accuracy of hauling speed.

Automated variable diameter cutting

Adopting fully automated swarfless cutting unit, of which the cutting thickness can reach 160mm. In addition, it is equipped with "one key automatic diameter adjustment", which enables the swarfless cutting machine for ultra-thick pipes to achieve easy operation, which can quickly complete the cutting of different specifications of pipes.

In general, measures such as selecting suitable materials and equipment, optimizing production processes, improving automation and quality control can effectively improve the production quality and efficiency of large diameter HDPE pipeline.