The plastic industry is one of the typical high emission and pollution industries, and it is also a potential area for China to achieve synergistic efficiency in pollution and carbon reduction. Green production has become a trend in the development of the plastic industry, and the raw materials, processes, products, and industries related to plastics are also pressing the "acceleration bottom" of green development. Accelerating the promotion of energy conservation and efficiency improvement in production is not only beneficial for improving production efficiency and reducing production costs, but also for promoting the green production transformation of enterprises.

Liansu Machinery closely follows the industry development trend and provides customers with automated green production solutions based on the market and customer needs, providing assistance for green production. Liansu Machinery independently developed and produced the high-speed mixer.With the high-efficiency and energy-saving features, the mixer has been highly welcomed by customers since promotion and significantly improved quality and efficiency for customers.

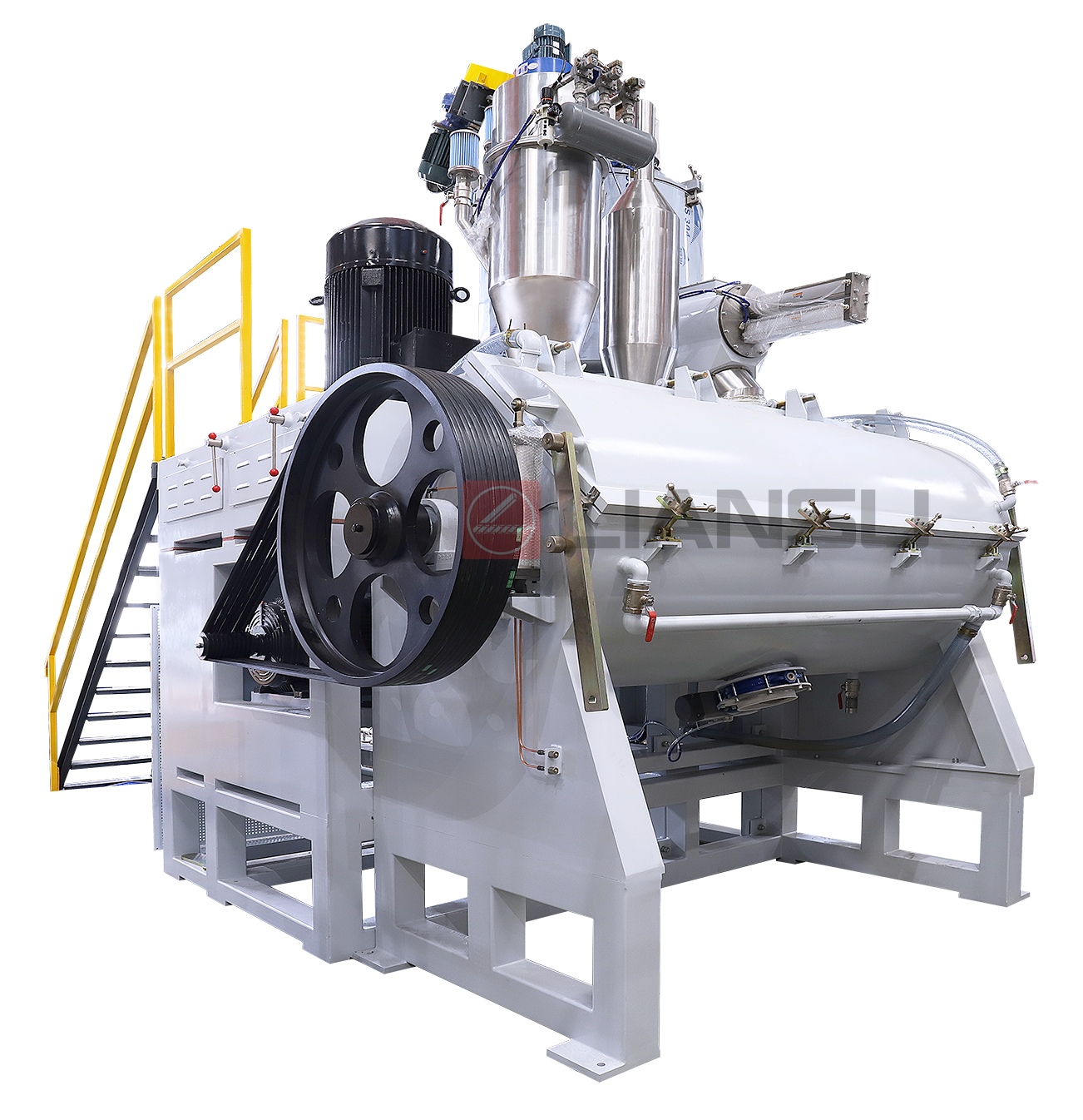

GRH500/LH1500 High Speed & Cooling Mixer Combo

GRH1000/LH3000 High Speed & Cooling Mixer Combo

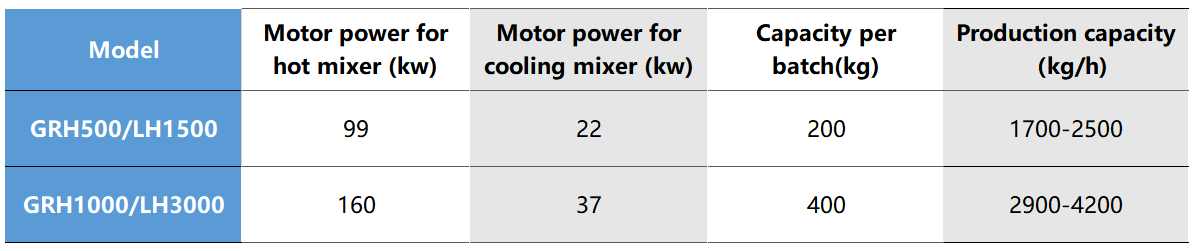

Main Technical Parameter

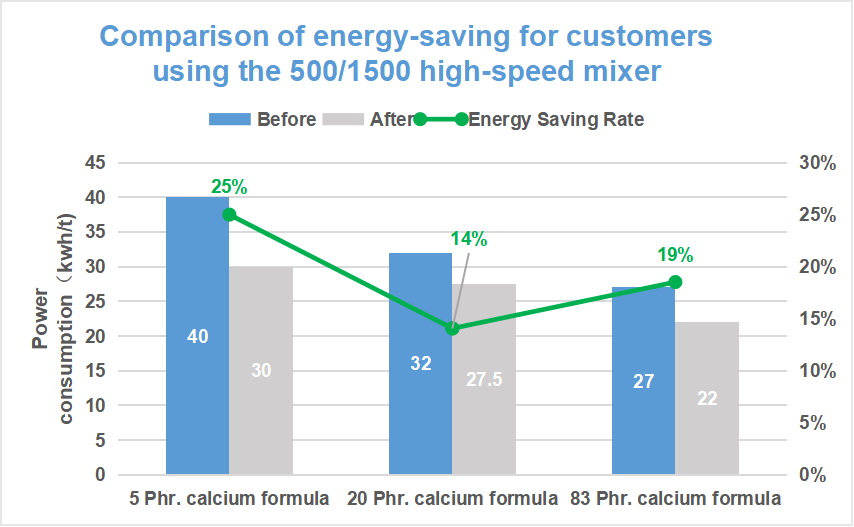

Make every effort to save energy and make plastics in sustainable production

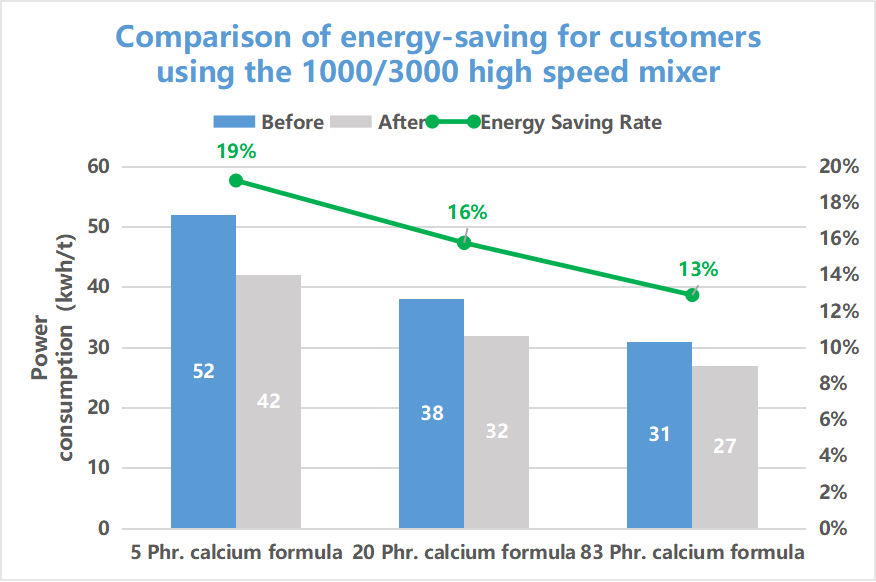

The plastic industry, as a high-energy consuming industry, consumes a large amount of electricity, resulting in high production costs and lack of competitiveness in products, which affects the economic benefits of enterprises. The Liansu high-speed mixer adopts an ultra-high efficiency permanent magnet synchronous motor, which has a high energy saving rate. The comprehensive energy saving rate is 10% - 20% (compared to conventional asynchronous motor drive), continuously providing energy-saving assistance to customers, reducing production costs, and promoting sustainable development of the enterprise.

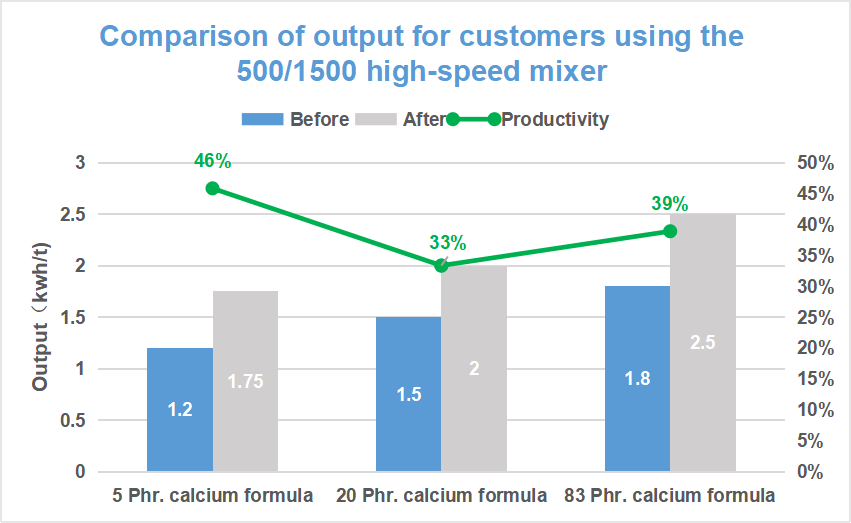

High efficiency in increasing production and make plastics in green production

The Liansu high-speed mixer adopts high torque synchronization , special structure blades and high load bearing groups, with high torque and overload capacity. The discharge adopts a dual mode control of time and motor current, which not only controls accurately, but also greatly saves mixing time, ensuring stable and reliable product quality. In addition, the cold mixing mechanism adopts a large area water ring cooling design and comes with a power driven forced internal cooling circulation system itself, resulting in high cooling efficiency. Due to the more efficient, uniform, and stable mixing process, the product output and quality have also been greatly improved.