LlANSU is committed to providing Full Stack Plastic Pipe Manufacturing Solutions for pipe plant, from raw materialhandling system to extrusion, as well as digitalized and transparent management of the production processing. LIANSU provides a full set of technical solutions.

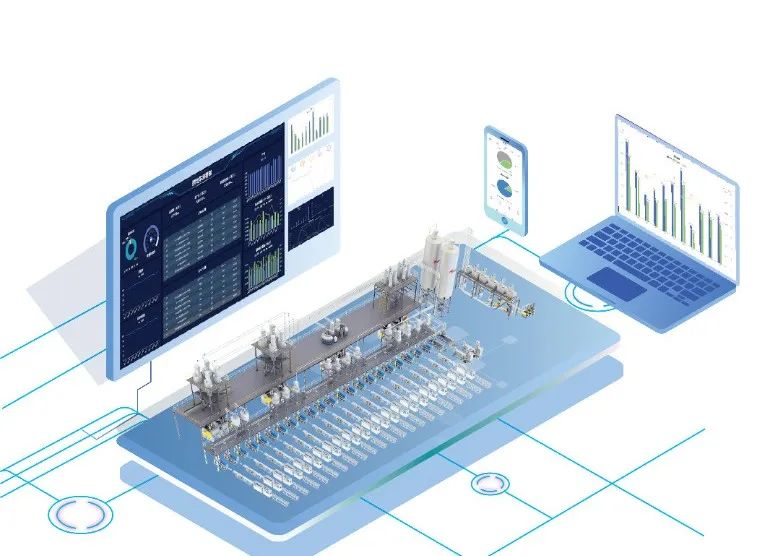

LIANSU has an experienced technical team with over 30 IT engineers and hardware engineers, and can customize the information management system of plastic processing equipment according to customer needs. For plastic extrusion equipment, feeding auxiliary equipment and automatic feeding system, we can realize the networking, communication, data collection and analysis of equipment, so as to digitize production equipment and visualize the production process.

Features

Functions

Data Browsing

Equipment Monitoring

Production Management

Energy Consumption Management

Equipment Maintenance

Data Collection

Data Application

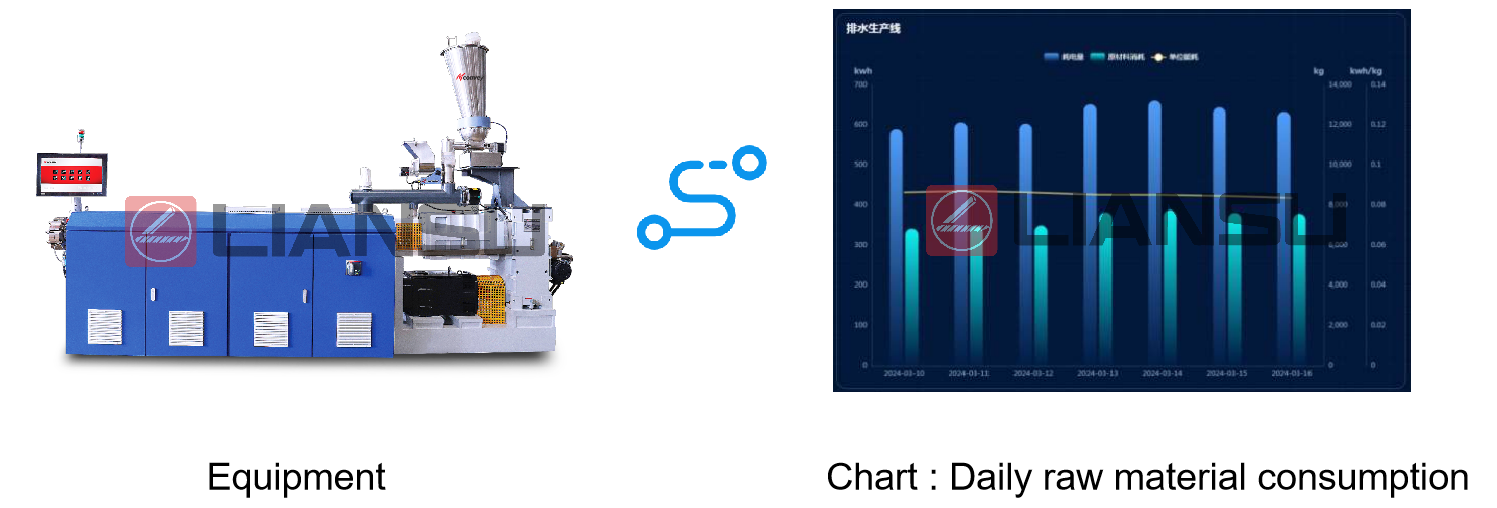

Through analysis based on raw material consumption data in equipment, products, and orders, the actual material consumption of production orders can be statistically analyzed.

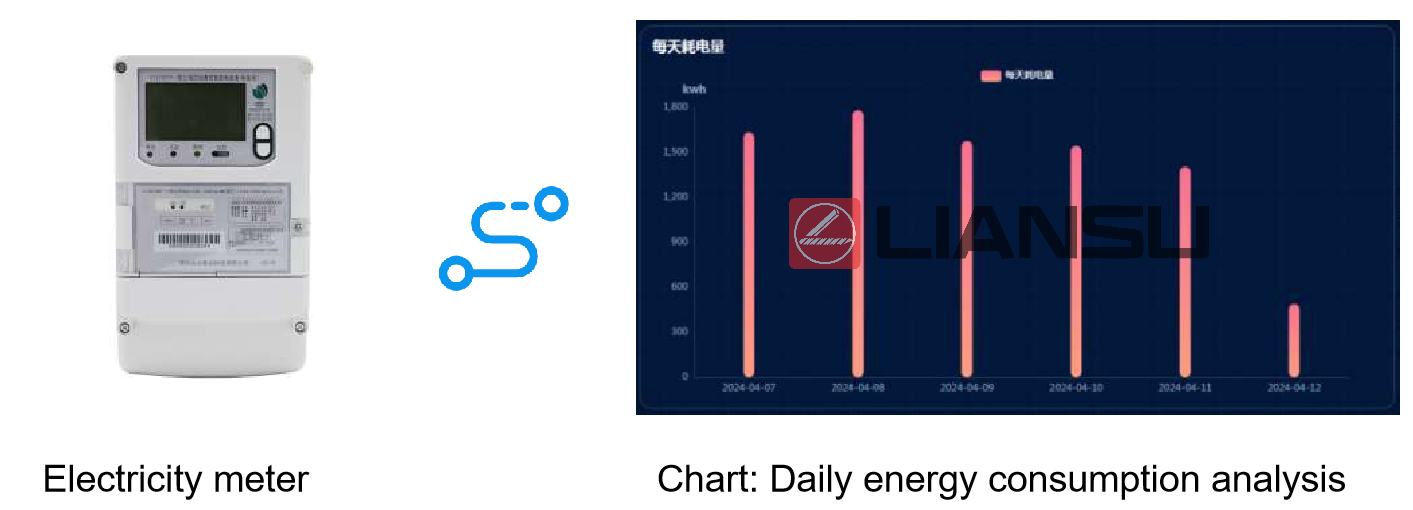

· Energy Consumption Analysis

Through analysis based on equipment, products, and orders, we can find energy-saving points to improve management, and reduce energy costs.

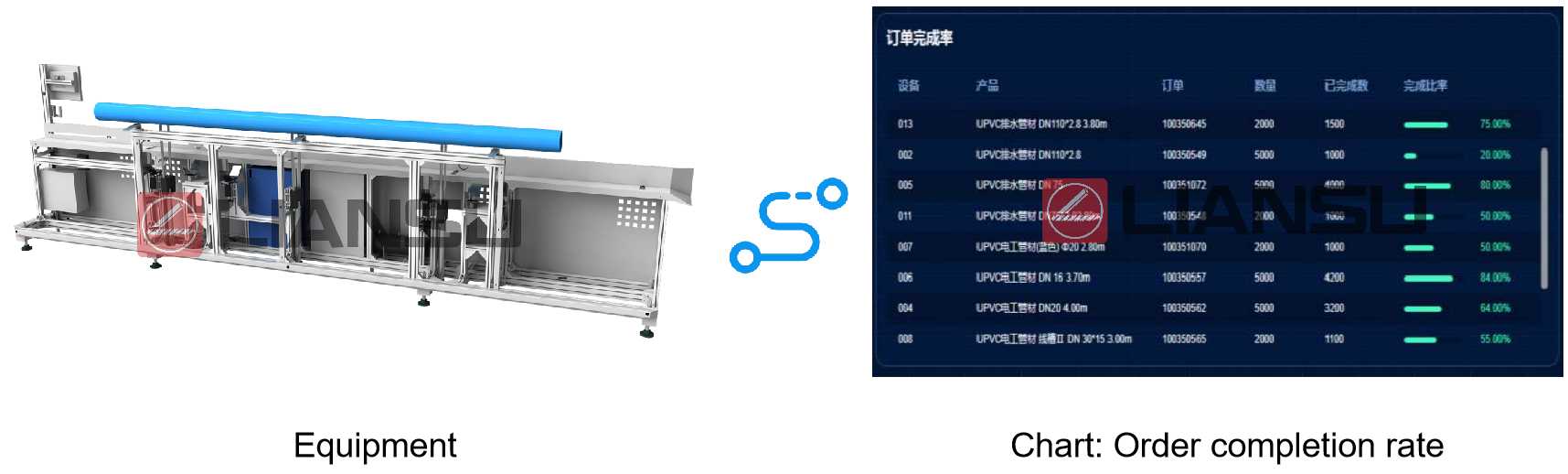

· Production Reminder

The number of completed orders and the completion rate are updated in real time, and prompt reminders are given when order production is completed to avoid waste caused by overproduction.

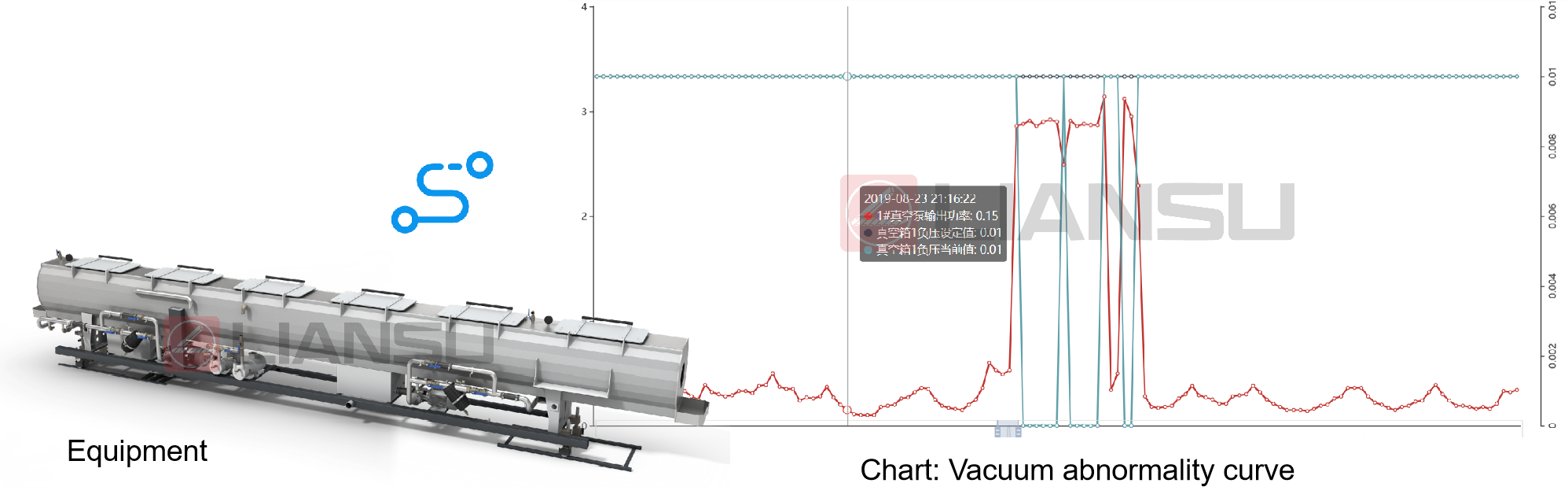

· Quality Tracking

Vacuum abnormality alarm can quickly locate the problem time point and visualize the duration of vacuum abnormality.

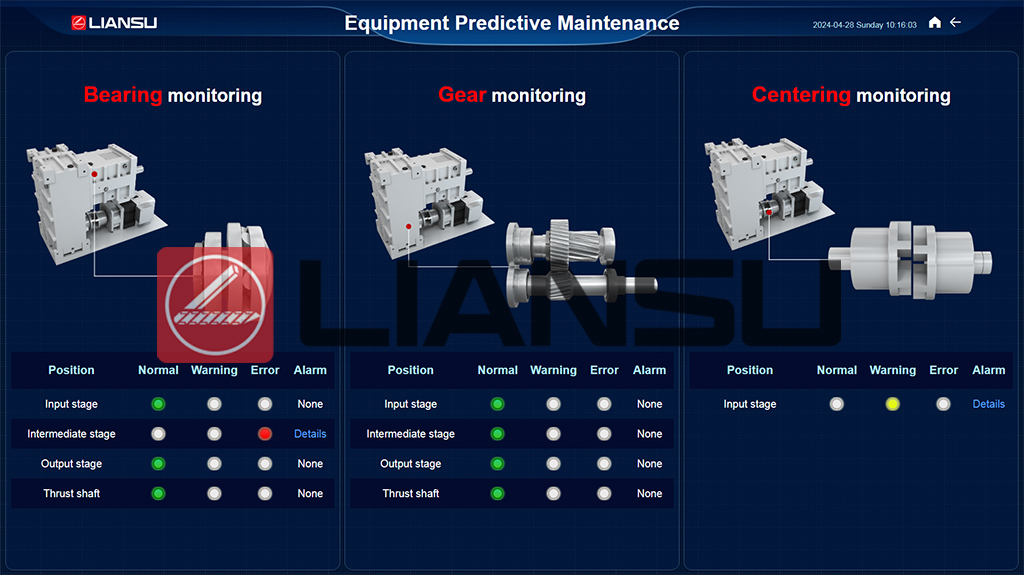

· Equipment Maintenance

Carry out predictive maintenance on the key components and parts of the host, monitor them in real time, and issue timely warnings on their sub-health status.

Through equipment networking collection and data analysis, the plastic processing equipment IoT system can enable enterprises to achieve efficient, intelligent and sustainable production operations. For more product information, please contact us!