For rigid PVC and formula material, the main advantages of Liansu mixing unit:

◎High speed compound mixer:Adopt high torque, ultra-high efficiency permanent magnet synchronous motor, high energy saving rate, high torque, high overload capacity.

◎With ultra-low no-load current (less than 1/10 of AC asynchronous motor), it is more accurate to use no-load current to detect hot mixing discharging time than traditional time control.

◎The high-speed mixer adopts special large load blade design, wear-resistant material, long service life and good mixing effect.

◎The bearing pedestal of high-speed mixing machine adopts heavy load bearing, which can bear large torque drive.

◎The comprehensive energy saving rate of mixing is 10~20% (relative to conventional asynchronous motor driving).

◎The cold mixing mechanism adopts large area water ring cooling design, and has its own power forced internal cooling circulation system, with high cooling efficiency.

Now we offer models:

| High speed mixing machine Power kw | Cold mixing motor Power kw | The max. output kg/h |

GRH500/LH1500 | 88 | 22 | 2500 |

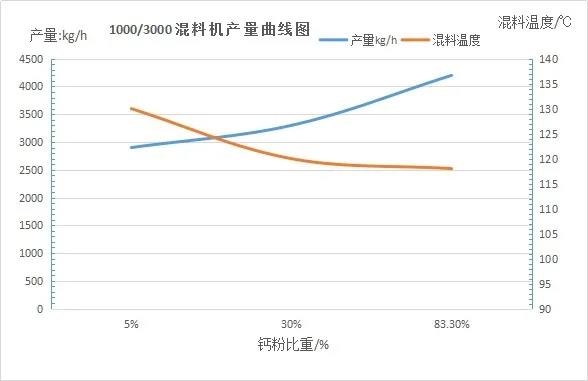

GRH1000/LH3000 | 160 | 37 | 4200 |