PVC pipe's application in everywhere of our daily life. With the development of market demand and continuous technological innovation, PVC pipes are widely used in water supply and drainage system, electrical pipelines, ventilation system, cableduct, chamical industry and so on.

PVC Pipes

PVC pipes are mainly divided into PVC-U, CPVC, PVC-O and PVC-M.

PVC-U pipe: the most common PVC pipe, also known as rigid PVC, is widely used in building drainage because of its high strength, corrosion resistance, easy installation, non-toxic and non-polluting.

PVC-C pipe: high temperature and corrosion resistance, flame retardant and fireproof, excellent insulation performance, green and environmentally friendly. It is mainly used in fire-fighting piping system, industrial piping system and hot and cold water piping system.

PVC-O pipe: a new type of PVC pipe with high strength, high toughness, high impact resistance, and fatigue resistance. It is made by oriented processing of long chain molecules of PVC-U pipes produced by commonly used extrusion methods. The wall thickness of the pipe is relatively thin, greatly saving materials and reducing costs. It is mainly used in water supply pipelines, mining pipelines, non excavation laying and repair pipelines, gas pipelines, and other fields.

PVC-M pipe: Modified PVC pipe, which enhances the toughness and impact resistance of PVC pipes by adding modifiers. It is suitable for situations that require durability and high impact resistance, especially suitable for use in cold areas or environments prone to impact.

PVC Pipe Extrusion Line

In order to produce high-quality PVC pipes, in addition to the stability of material and formula quality, there are important requirements for the design of the extrusion screw and mold, the stability of the control system and others.

The PVC pipe extrusion line developed and designed by Liansu is capable of producing PVC pipes with diameters ranging from 16 to 1000mm, covering different types to meet the production needs of different customers.

The production line mainly consists of extruder, die head,vacuum forming tank, haul-off unit and cutting machine, and the control system can choose the self-developed FLEXCON system to realize the transparent management of production data. The downstream can be equipped with optional automated supporting equipment such as on-line socketing machine and on-line automatic packaging machine.

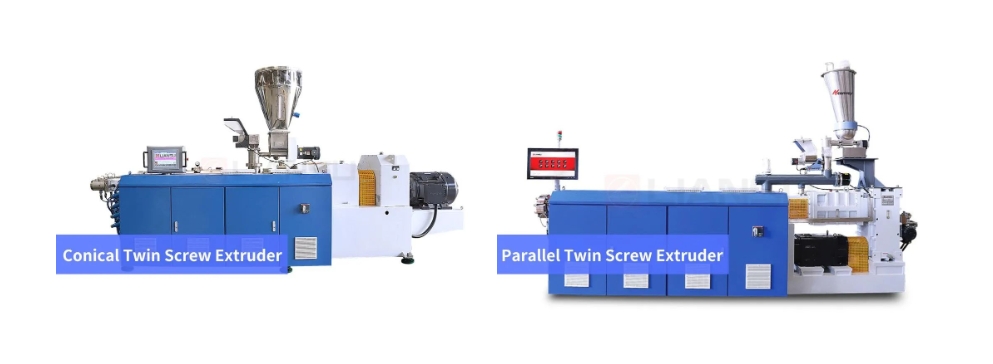

The extruder is equipped with a large L/D ratio parallel twin-screw or conical twin-screw main machine, and the reasonable screw design ensures high output and good material shear and plasticization quality. In addition, the extruder adopts special permanent magnet synchronous servo motor, which is efficient and energy-saving.

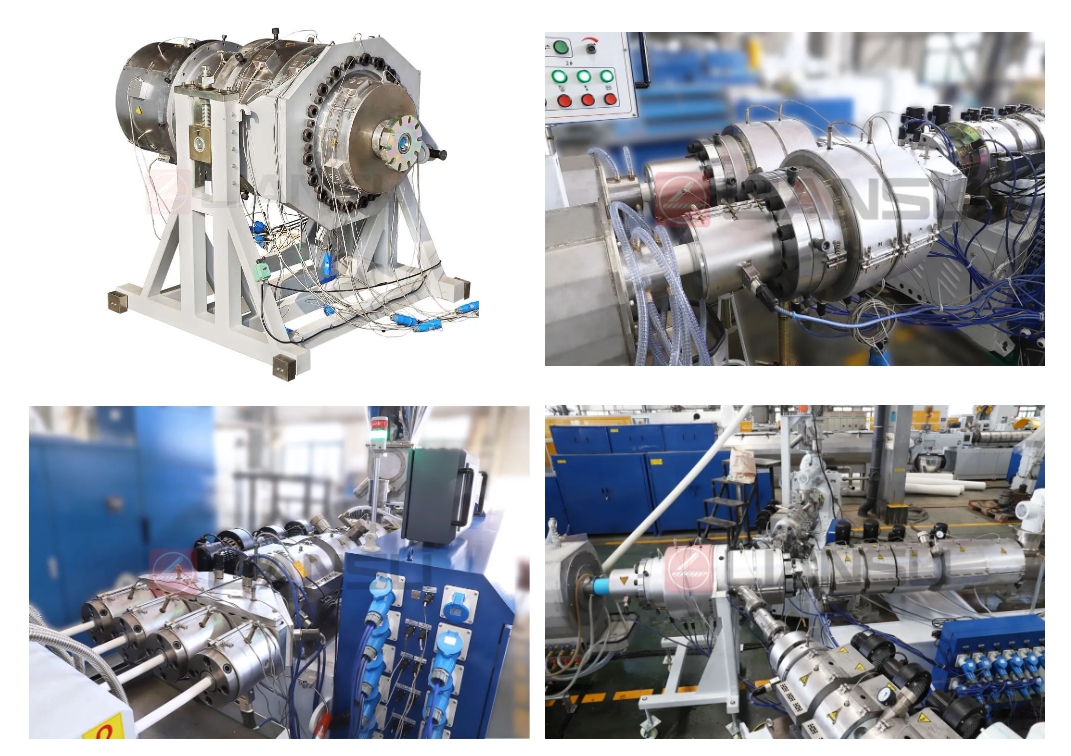

Die Head

The die head PVC pipe head adopts distributor to ensure smooth and balanced flow of materials, which is very suitable for handling raw materials that are extremely sensitive to temperature. The die head is divided into single-layer and multi-layer structure, and the maximum size is 1000mm for single-layer and 800mm for multi-layer .

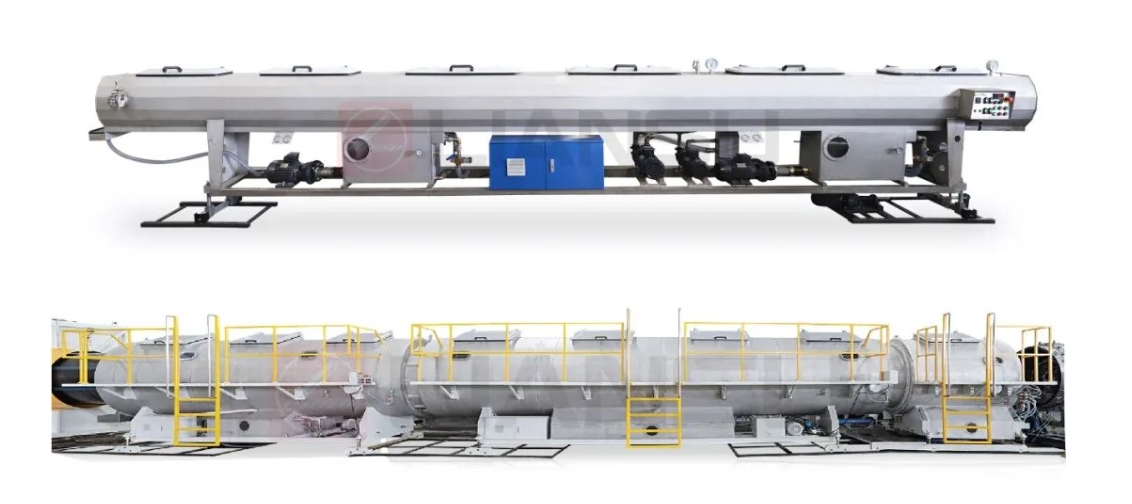

Vacuum Forming

The vacuum forming tank adopts fully automatic negative pressure closed-loop control system to ensure stable forming of the pipes. By automatically adjusting the speed of the vacuum pump, it can achieve the energy-saving with low noise.

Hual-Off

The synchronized servo drive solution is adopted for the haul-off unit and pipe leading device, which ensures stable speed range of over 50 times and reducing waste.

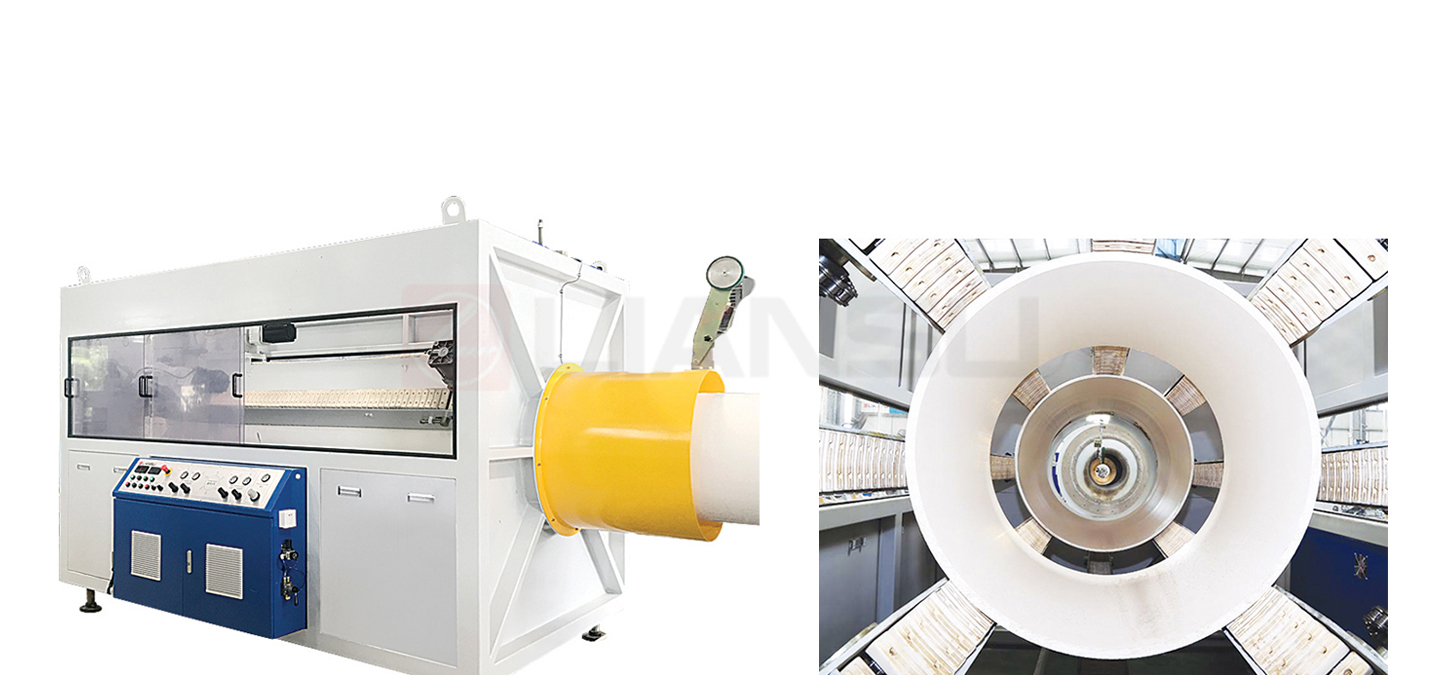

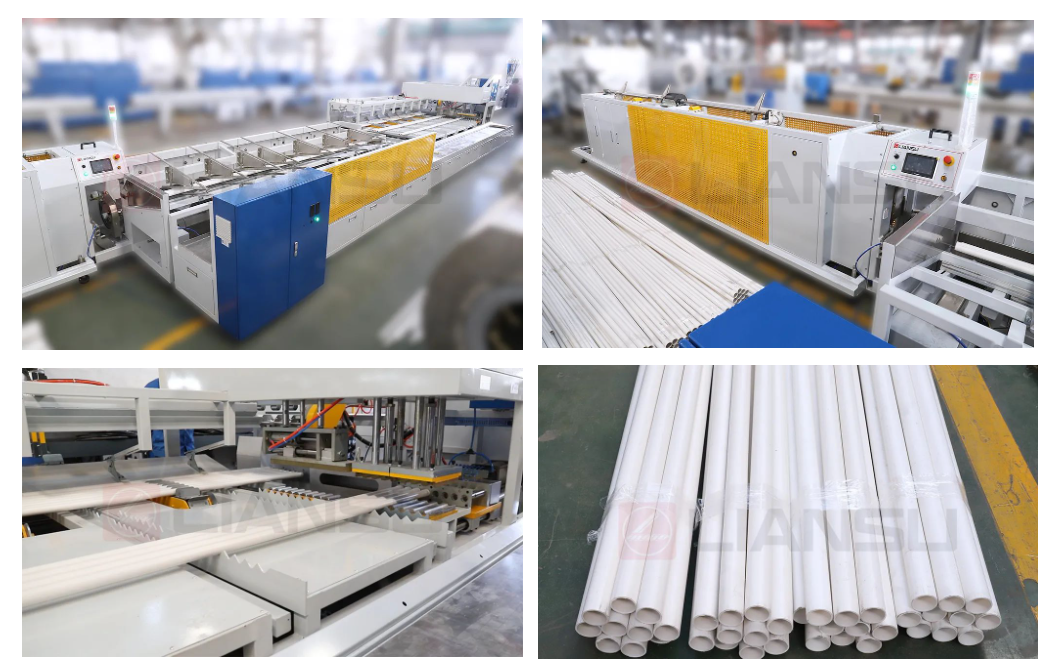

Cutting

Adopting planetary cutting, multi-point clamping pipe, lens-type sealing structure; The self-balancing counterweight and automatic profiling structure ensures uniform chamfering. And the pipes diameter below 200mm adopts swarfless cutter, ensuring stable cutting and avoiding cleaning troubles.

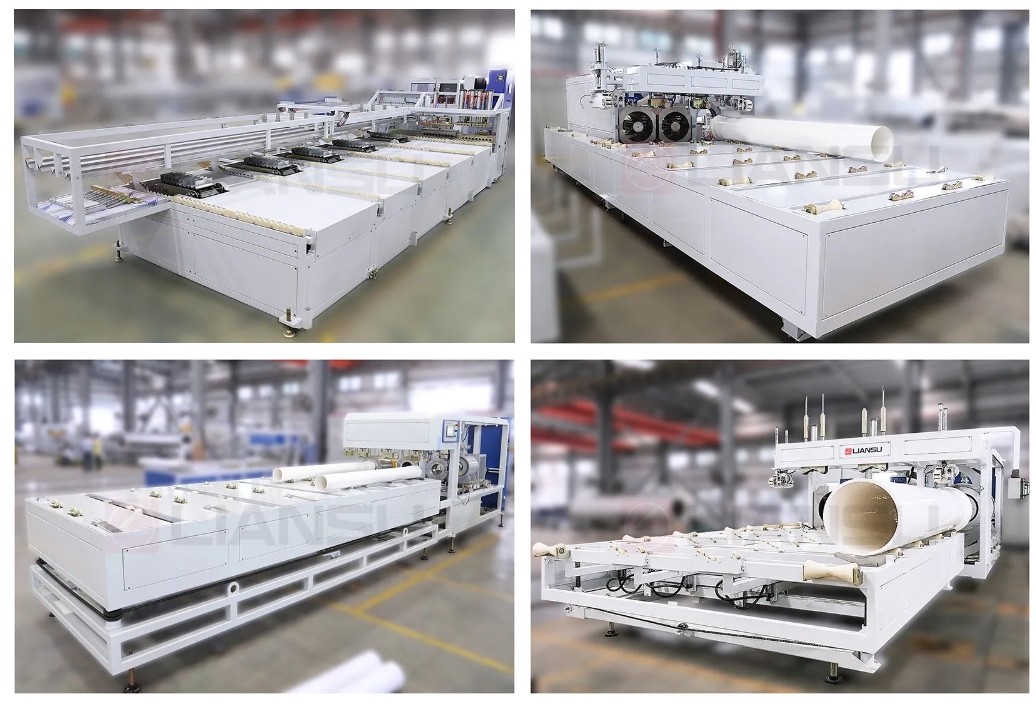

The optional online socketing machines are available, and Liansu's self-made socketing equipment provides various types of sockets to meet the needs of different pipe diameters. Single station, double station, 4-station, and 10 station socketing units can be selected according to the production line speed, helping efficient production.

On-line Automatic Packaging Unit

The optional online automatic packaging unit provides various packaging methods such as bundling, bagging, and film wrapping, which can efficiently save manpower.

FLEXCON+Flexible Control System

The whole line can be equipped with FLEXCON+ flexible control system, which realizes the collection and processing of equipment production data, simpler and more effective maintenance reminder. And it adopts closed-loop control from material metering, vacuum control, and finished product weighting.