The main machine is equipped with special permanent magnet servo motor for extrusion, it is energy-saving and efficient, saves more than 15% of energy.

The whole line is equipped with data acquisition system to store and analyze production process data, visualize production process and improve management efficiency.

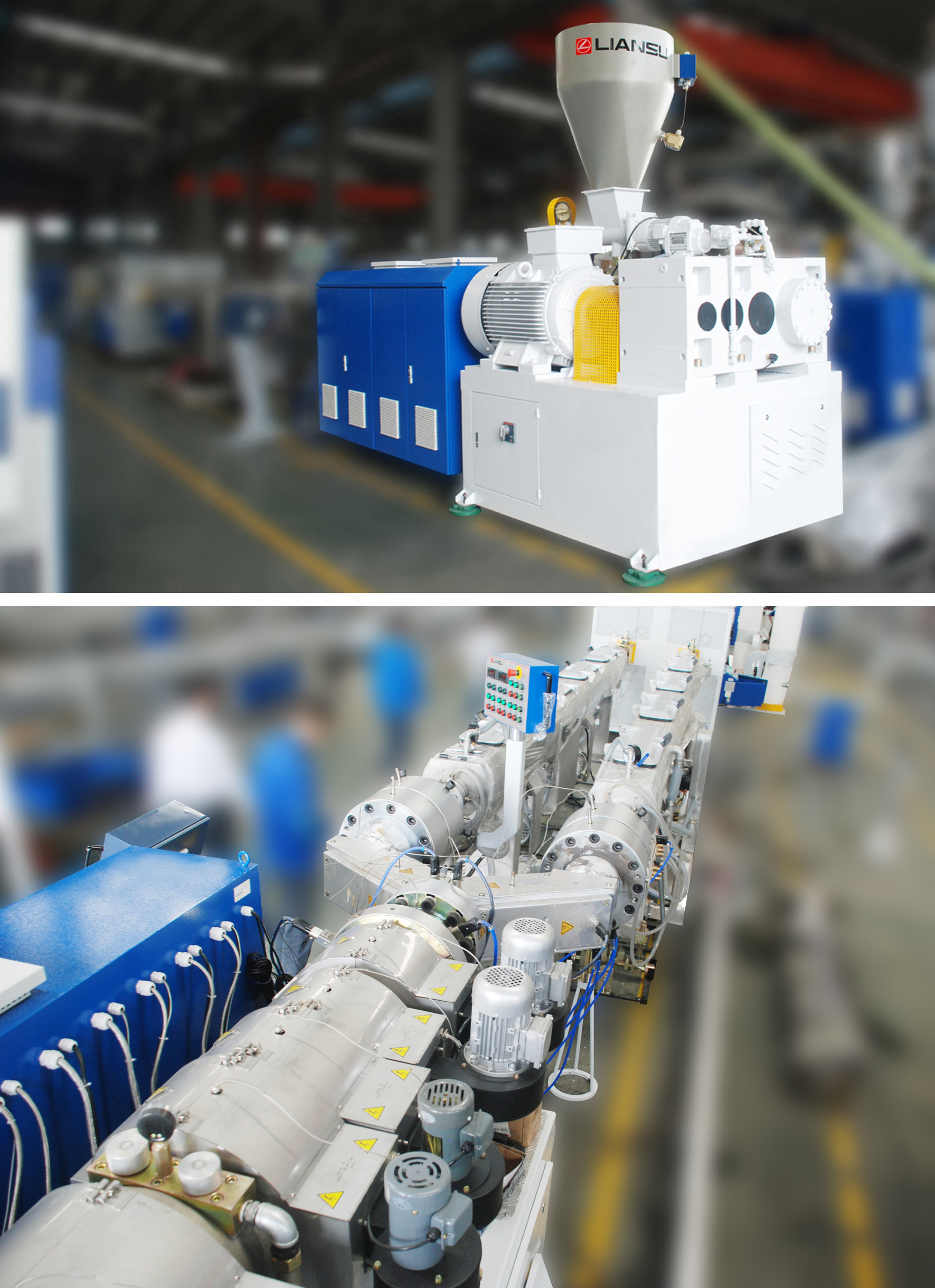

Extruder Part

The output of LSPD93 parallel twin screw extruder with 32D L/D ratio can reach 500-550 kg/h.

Special screw flight design, screw has good adaptability to customer's formula, stable extrusion output.

Adopt high-torque precision reducer and the specially designed power transmission mode make the left and right output shafts power balanced, accurate in phase and satisfy the output of large torque.

High efficiency and low energy consumption permanent magnet servo motor cooperates with low loss reducer,elastic coupling can further improve the efficiency of the whole machine and effectively reduce noise.

The design of feeding,screw and barrel is suitable for the formula material of calcium and zinc,meets the national standard of pipe.

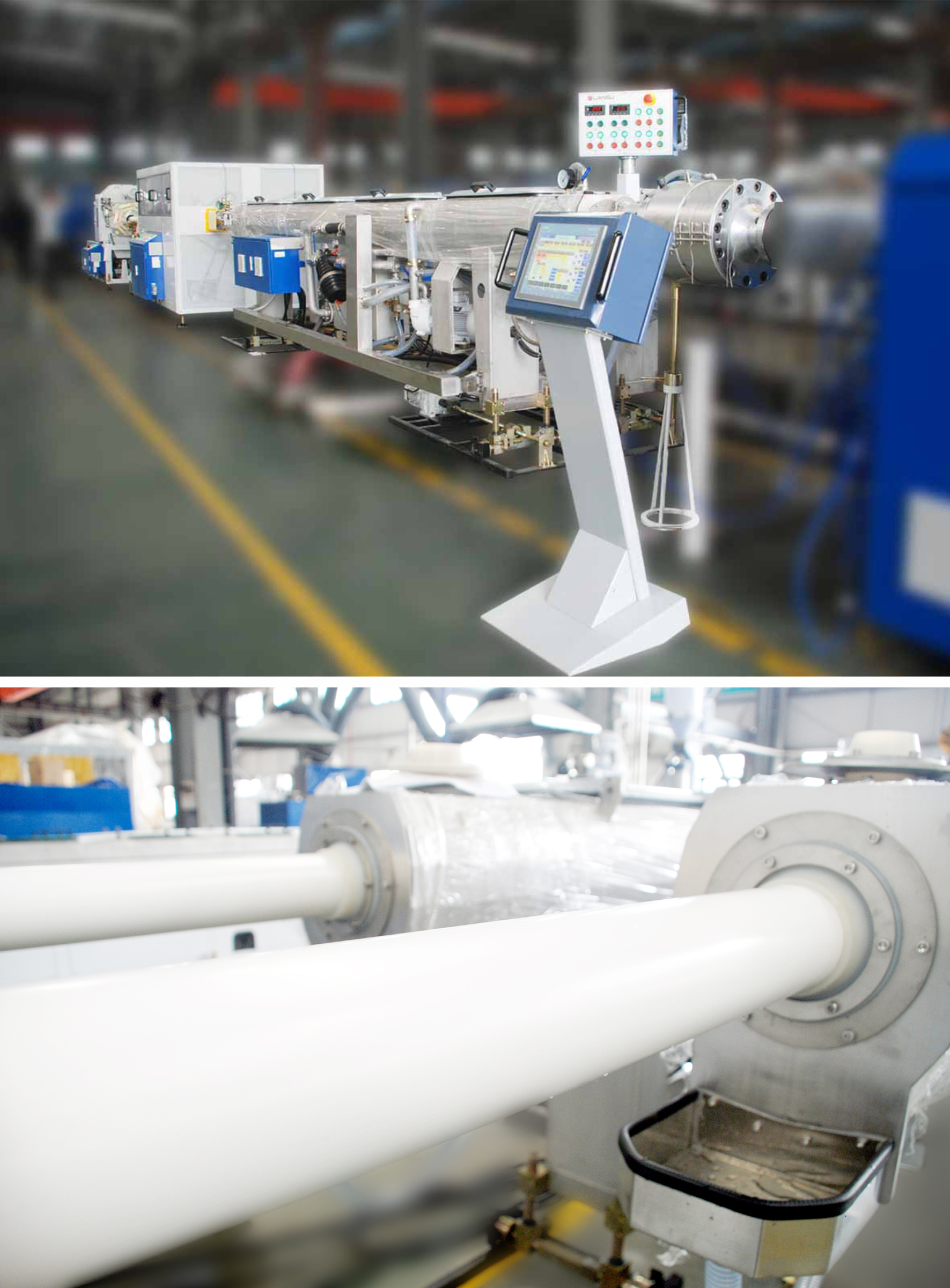

Extrusion Die

Use mature scaffolding structure to ensure the quality of plasticization.

Vacuum Tank

The whole body is made of stainless steel, which is durable

Smooth flow channel design, avoid decreasing water pressure caused by traditional elbow diameter reduction

Centralized drainage system, easy to operate

Automatic PID negative pressure regulation is adopted for vacuum tank, which saves more than 40% energy and greatly reduces noise.

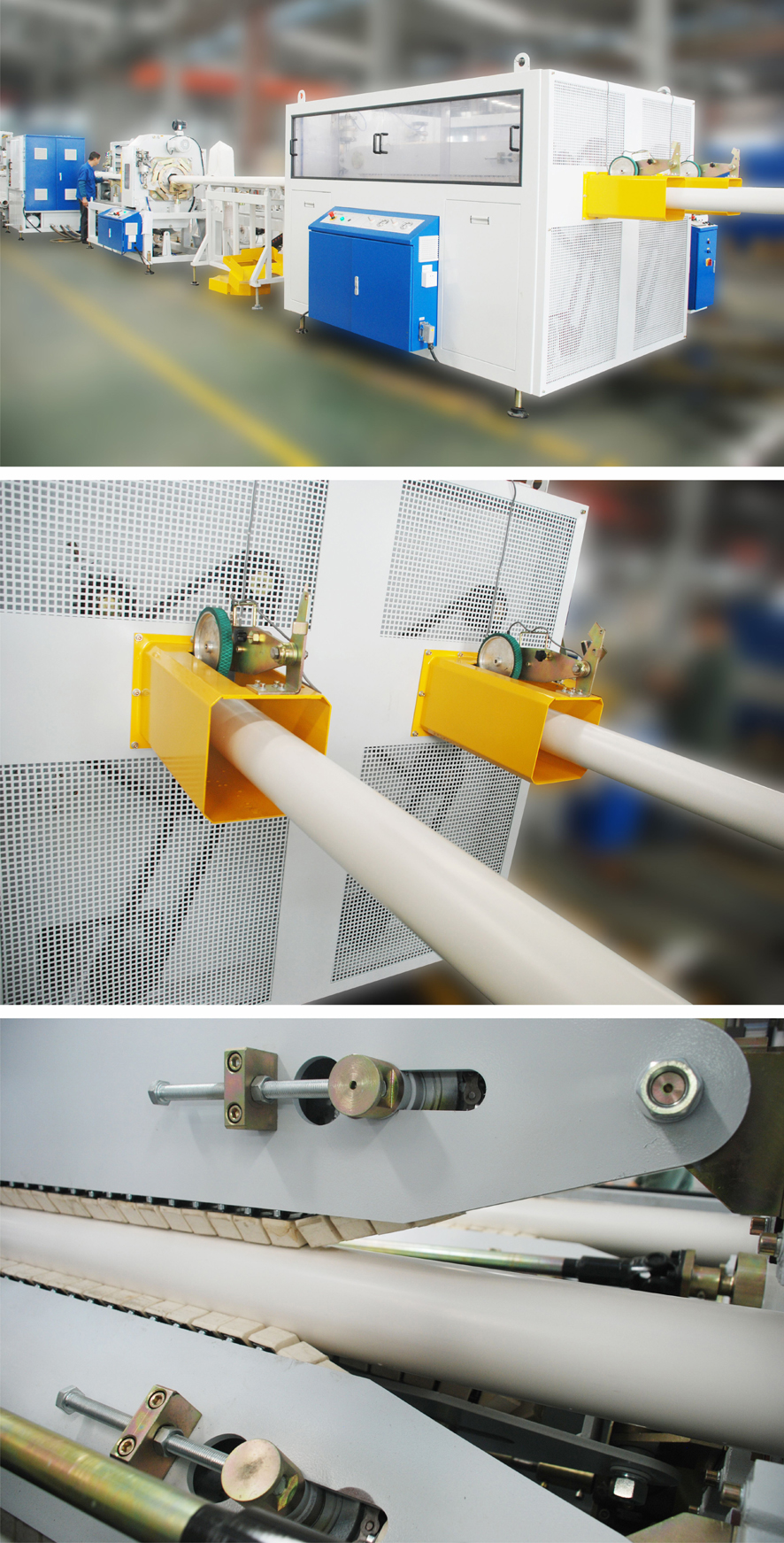

Hauling

High-efficiency servo motor cooperates with precision reducer, which has wide speed range and stable speed.

Cutting

Adopt swarfless cutting which will not produce polluted dust,clean space.

Packing Machine

On-line automatic plastic film bagging and packing, simple and stable structure, superior user experience.