Thickness:SDR 9 - SDR26

Automated Material Management

To ensure production stability and product quality, the production line is equipped with Mconvey automatic robot material debagging station and high-precision multi-component gravimetric blender to achieve automatic debagging and accurate dosing, ensuring accurate raw material feeding and stable performance of multi-layer pipes. In addition, the production line is also equipped with an efficient dehumidification and drying system to ensure the optimal moisture content of the material, improving production stability and product quality.

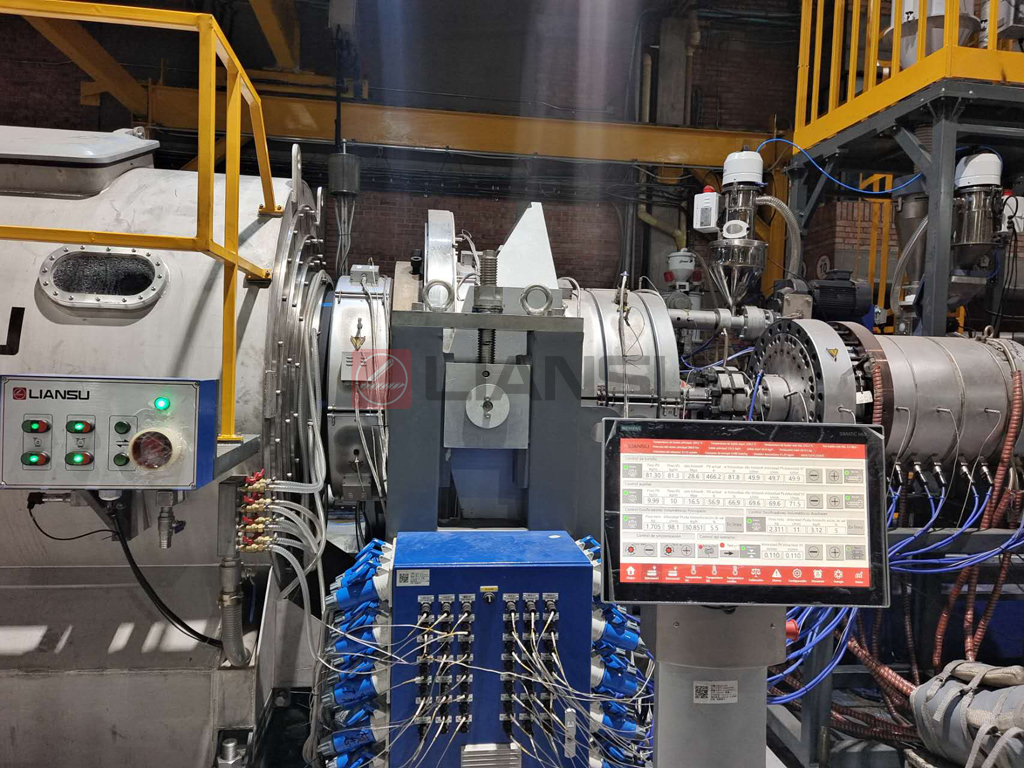

Efficient Multi-layer Extrusion

The production line adopts advanced 40 L/D high-efficiency extruder, combined with melt cooler and unique spiral pipe head design to achieve stable and efficient production of multi-layer pipes. While improving production capacity, the production line optimizes the metrial melting and cooling process, ensuring the uniformity and density of each layer of the pipe, greatly improving product quality and production efficiency, and being able to flexibly meet various specifications and application requirements.

Intelligent Production Management

The production line is equipped with FLEXCON+ flexible control system, which integrates control, data collection and processing functions to achieve equipment command issuance, production process monitoring and equipment maintenance. Customers can optimize production efficiency, reduce failure rate, and improve equipment reliability and maintenance management efficiency through real-time data analysis.