Hereunder we would like to introduce the production process of our Vacuum & Cooling Tank, and share more about how Liansu to maintain the good-quality products manufacturing in our internal plant.

In the process of plastic pipe processing, plastic material extrusion to calibration sleeve from extruder to die head and quickly calibrated by stable vacuum to ensure the standard dimension of pipe. The rapid forming of the pipe depends on the stability of the vacuum and the sealing effect of the tank to achieve high production and reduce waste.

Efficiency

Efficient and energy-saving with an energy-saving rate of 30%~85%.

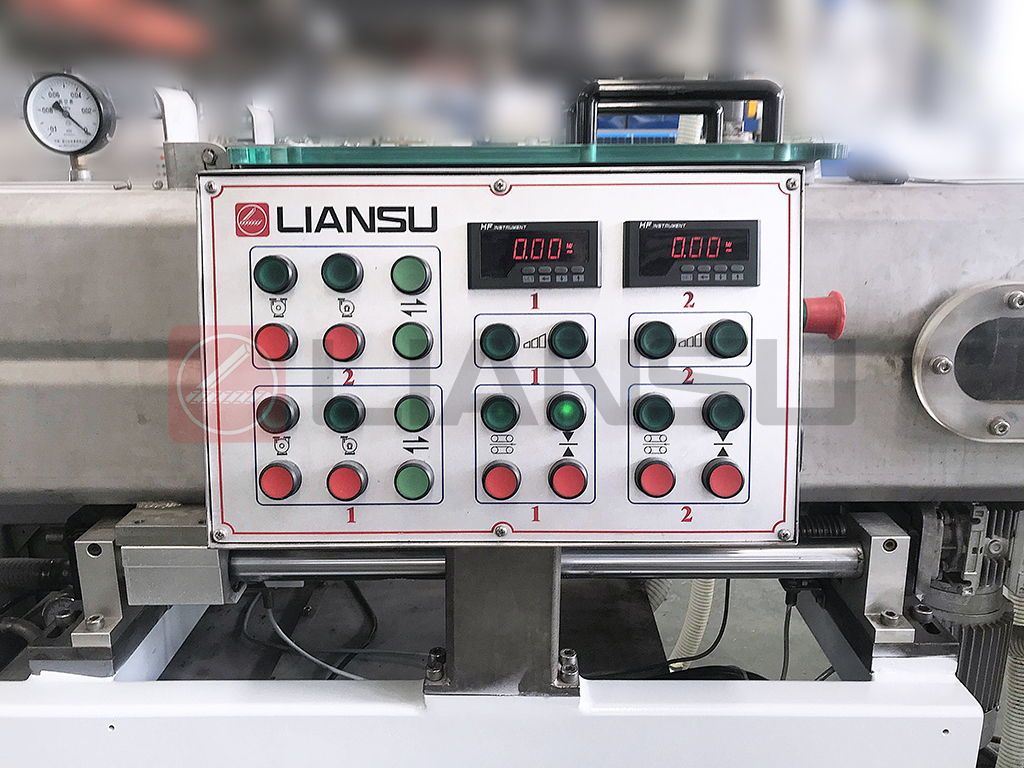

The vacuum forming tank produced by Liansu Machinery is independently and professionally researched and designed, and has obtained multiple utility models and appearance patents. It adopts a fully automatic negative pressure closed-loop control system. The HMI sets the required pressure, starts the vacuum pump, and transmits a signal to the frequency converter through the negative pressure sensor to automatically adjust the speed of the vacuum pump, quickly achieving a constant negative pressure without the need for manual pressure relief, thus achieving effect of energy-saving.Quality

Patented appearance design, good quality and durable

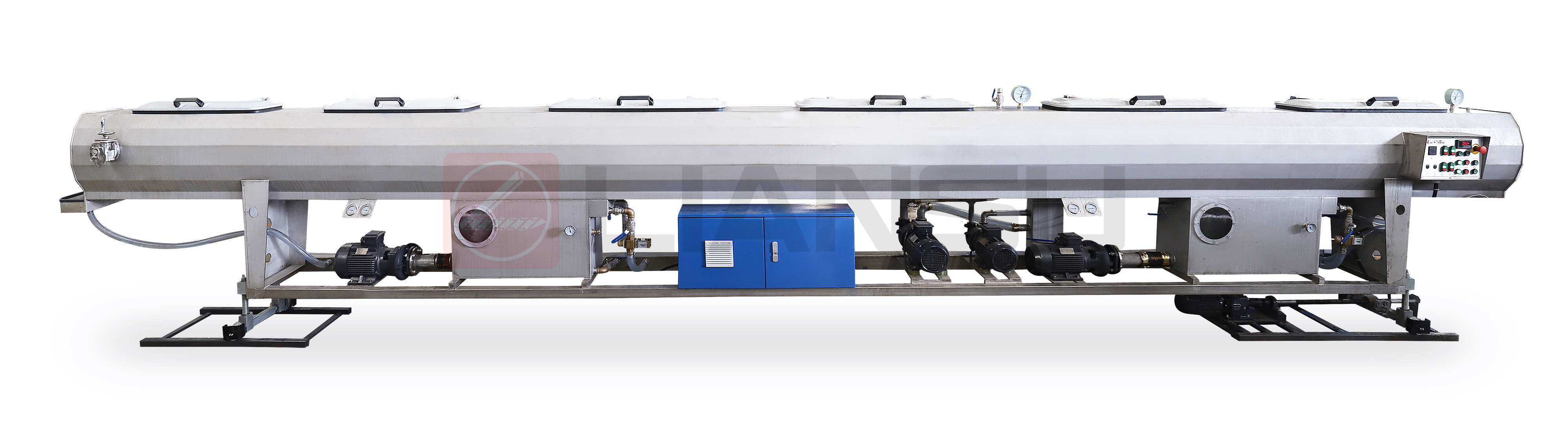

Tank model for pipe range 20mm~1000mm

· Adopting a polygonal structure with a deeper drainage groove at the bottom, good pressure resistance, beautiful and practical.

· Equipped with tempered glass covers, beautiful and elegant, suitable for production observation.

· Unique machine UDLR Up Down Left Right adjustment, simple and practical.

· Mechanical floating ball water level control, maintenance and repair free.

· The water temperature control adopts a combination of automatic and manual modes to avoid the risk of downtime maintenance.

· Unique centralized drainage and muffler.

· The vacuum tank adopts a two-chamber design, which saves energy and reduces consumption, and is suitable for the vast majority of pipe production.

· The vacuum tank is vacuum frequency conversion regulation, energy-saving and noise reduction.

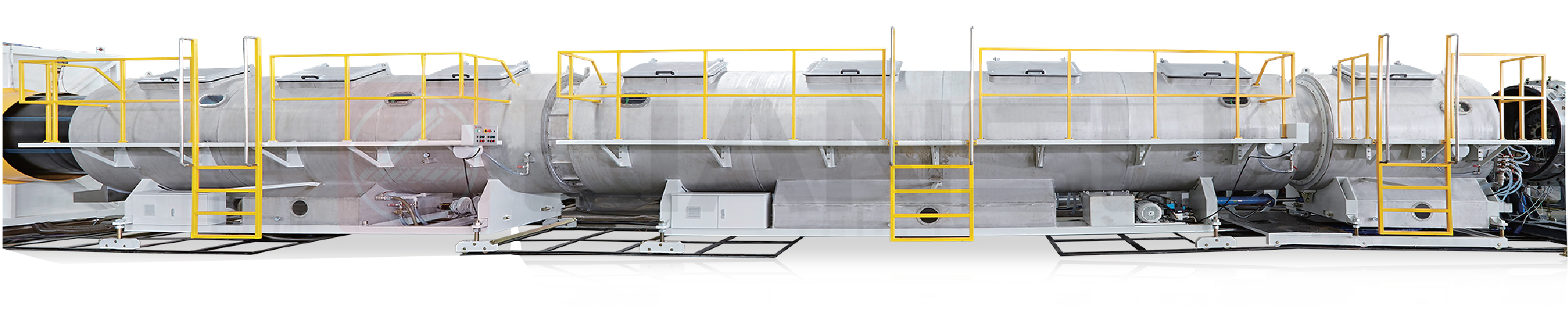

Tank for pipe range 1200~2600MM

· Adopting a circular tank design, with a calibration sleeve installed at the front end and limit support pins for easy installation.

· Human body height of the operating panel, the tank has an observation window, easy to observe the water level window, and temperature display table.

· The hydraulic controlled forward and backward movement mechanism, as well as the clutch separation mechanism between the 2/8 meter vacuum tanks, making the operation simple, stable, and reliable, and maintenance convenient.

· Equipped with a double filtration water supply filtration system, the filtration effect is better.

· The aviation plug design of electrical appliances between tanks facilitates conveying and simplifies installation.

· Independent vacuum mechanism design makes the mechanism more reliable; Variable frequency vacuum control, energy-saving and noise reduction.

Large

Large processing and assembly workshops with strong production and assembly capabilities

The tank components are produced and assembled by ourselves, in which a large number of pipe fittings in the vacuum tank are used in large laser cutting machine for laser cutting processing to ensure smooth cutting surface of the workpiece, achieve seamless splicing between pipe fittings, and reduce water pump pressure loss. At the same time, we has a large vacuum tank assembly workshop with strong production and assembly capabilities.

VIDEO

https://youtu.be/hBS0fEL6tmA?si=qD9kgw4MKGJk8iXU