As a new type of water pipe material, PPR pipes are mainly used as water supply pipes and due to their characteristics of light weight, anti-corrosion, easy installation, stable performance, heat resistance and insulation, and hygienic and non-toxicare, they generally used in hot and cold water systems, heating systems, and pure water supply systems, central (centralized) air conditioning systems, transport or discharge chemical substances piping systems, etc.

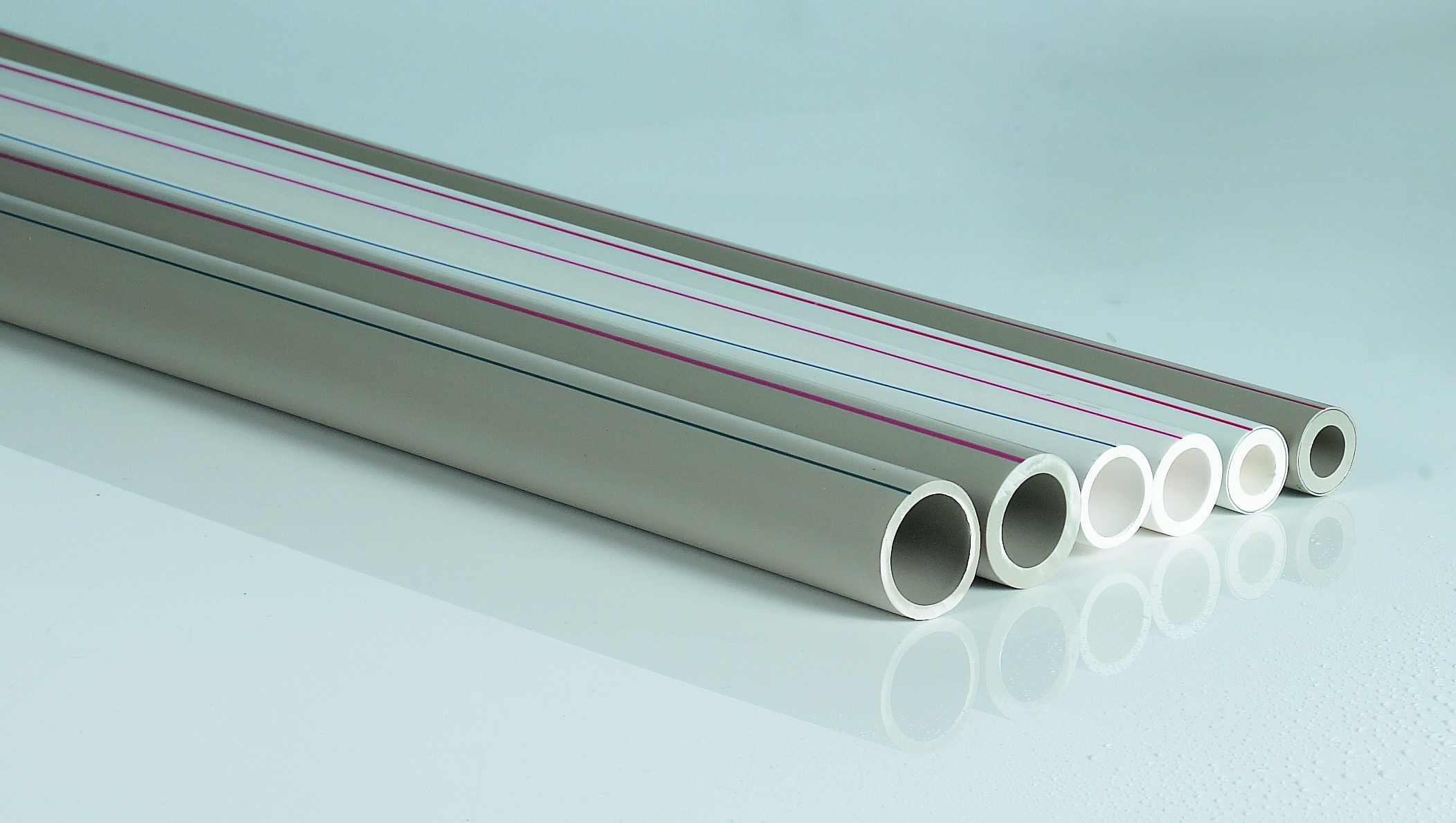

PPR Water Supply Pipe

The long-term normal working temperature of the water delivered by PPR water supply pipes is 70C, and the high temperature resistance can reach 95°C in short-term use. It can be used for both cold water pipes and hot water pipes, and it is hygienic, non-toxic, corrosion-resistant, and non-scaling. Features, can also be used for pure drinking water pipes.

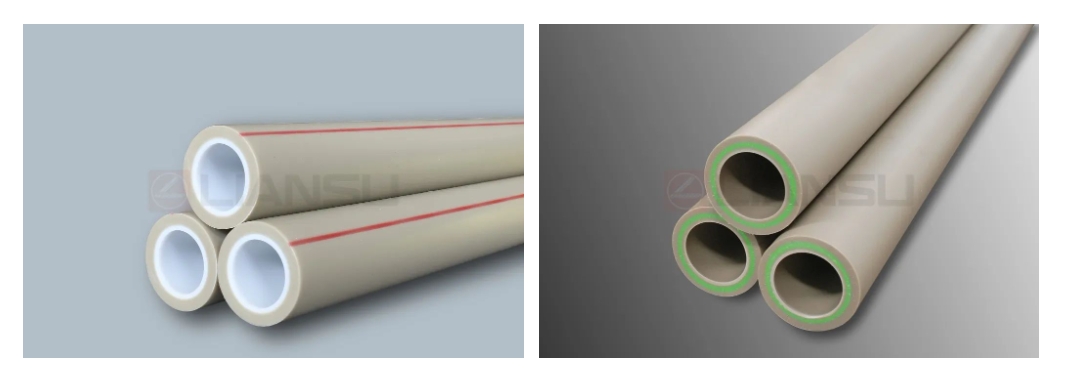

PP-R Co-extrusion Water Pipe

The pipe can effectively prevent the penetration of oxygen and light, ensure the pipe clean, and not affect the water quality and is suitable for drinking water transportation. Among them, PPR fiberglass coextrusion pipe adopts multi-layer co-extrusion technology, which can effectively isolate the air into the pipe, thereby inhibiting the growth of bacteria and moss to keep the water clean. It is the first choice for pure water pipes.

PPR-Aluminum Composite Pipe

The pipe has five-layer structure, PP-R - adhesive layer - aluminum layer - antibacterial layer - PP-R. It has the excellent properties of PP-R pipes and aluminum-plastic pipes, with temperature and pressure resistance, acid and alkali resistance, small expansion coefficient, light and oxygen penetration.And it has more advantages than ordinary PP-R pipes in heating, and is widely used as connecting pipes for various heating equipment.

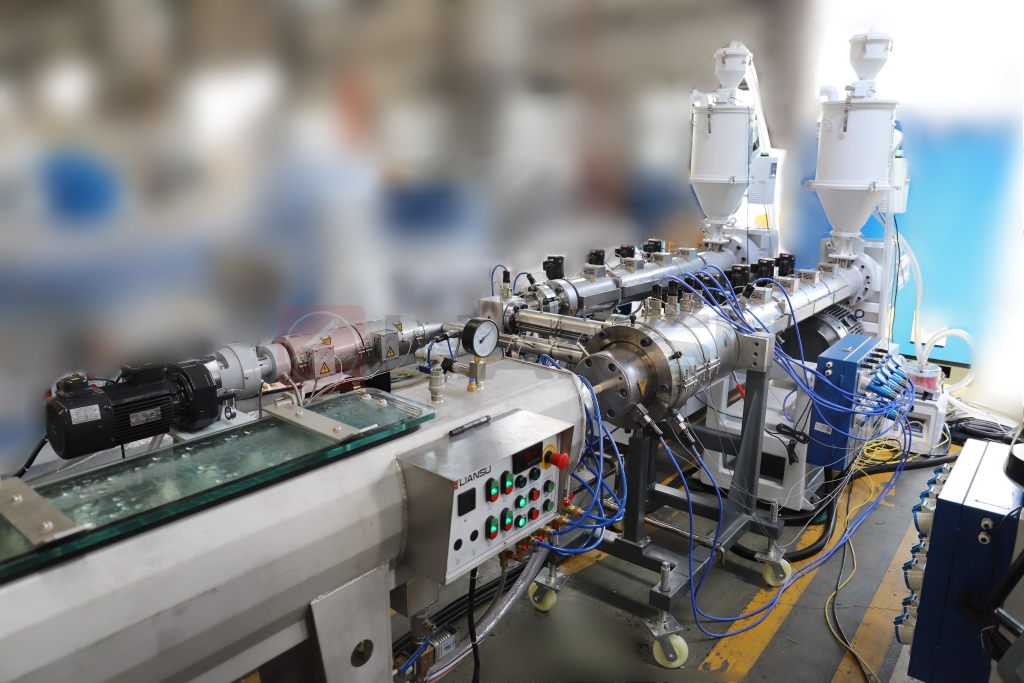

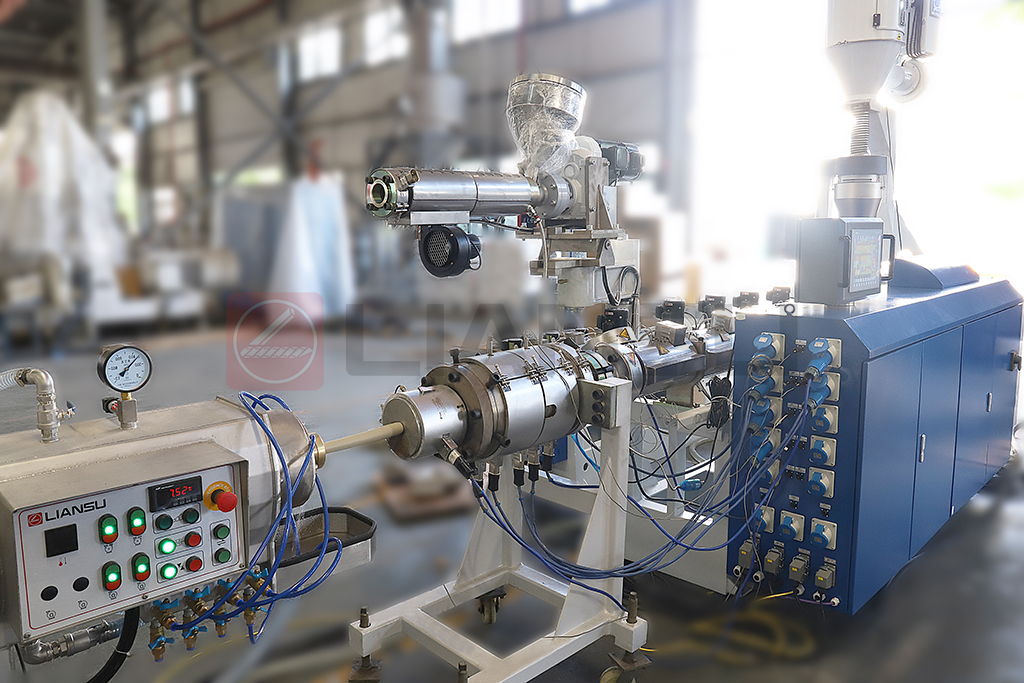

Liansu PPR Pipe Extrusion Line

To meet the market demand of PPR pipe structure and performance, Liansu developed and provides different types of PPR pipe extrusion lines, Pipe diameter range from 16 to160mm which can meet the needs of PPR single-layer, double-layer, three layer and four-layer coextrusion pipes. For extrusion lines, single-station or double-station extrusion equipment can be selected for pipes below 32MM, with maximum extrusion capacity of 550kg/h,providing high-quality PPR pipes production guarantee.

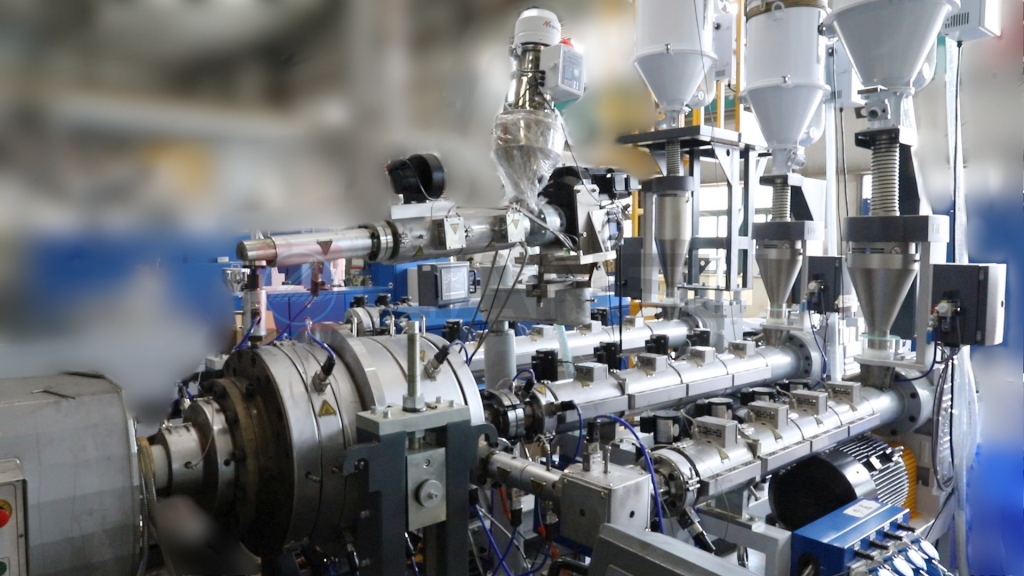

Extruder

Adopt screw design with large 40 L/D ratio to achieve high output and energy saving. The extruder can be integrated with online gravimetric doser for masterbatch, also can produce single layer and multi-layer PPR pipes. The position of co-extruder adopts back-type structure to save space.

Dide Head

The single or multi-spiral die head structure is suiablt for single or multi-layer structure with uniform wall thickness. The calibrating sleeve adopts forced water cooling at the inlet with high speed and stability.

Single Layer Extrusion Die Head

Double Pipe Extrusion Die Head

Multi Layer Extrusion Die Head

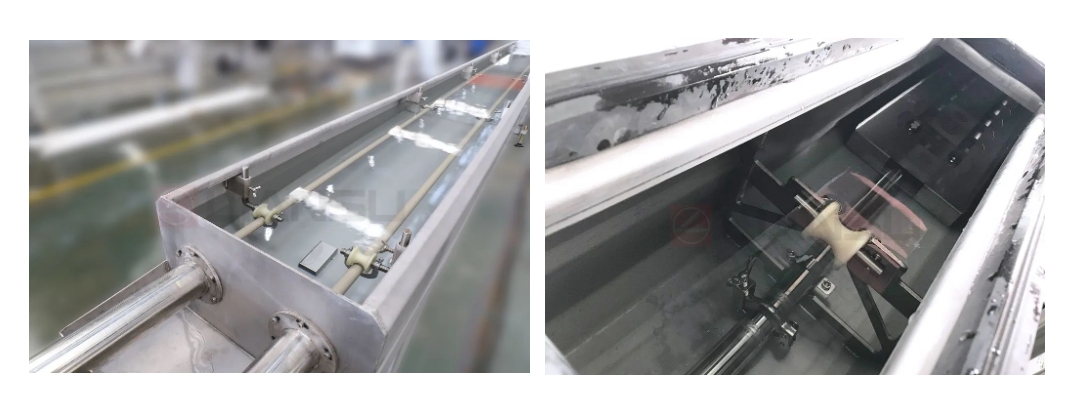

Vacuum Forming

It adopts fully automatic negative pressure closed-loop control system to ensure stable pipe forming, energy saving and noise reduction. The water tank is air or water-tight to reduce the vibration of high-speed production pipelines. It is equipped with vortex water tank and water pressure stabilizing device to reduce water bubbles and ensure stable water pressure.

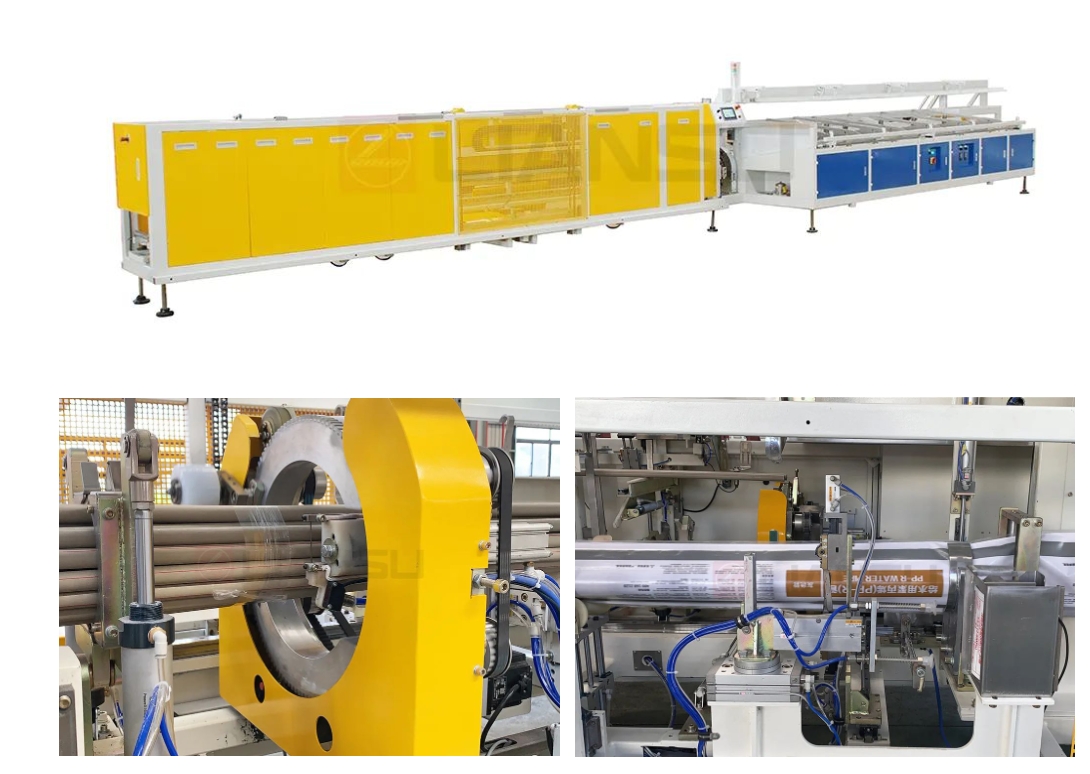

Haul-Off

It adopts servo control to stable speed range of over 50 times and high-speed and stable hauling.

Cutting

The pipe line adopts chipless cutting, and the cutting is stable and accurate. The cutting machine of small diameter adopts fly-cutter cutting , which can provide dual-station independent control, and the fixed length adopts "PLC-free control", which is simple,convenient, and low failure rate.

Package

A fully automatic packaging unit can be configured to provide PE bag packaging, woven bag sewing packaging and other packaging methods. The film wrapping and bagging are performed simultaneously, and the servo control is used to ensure high efficiency and stability.

Customer cases