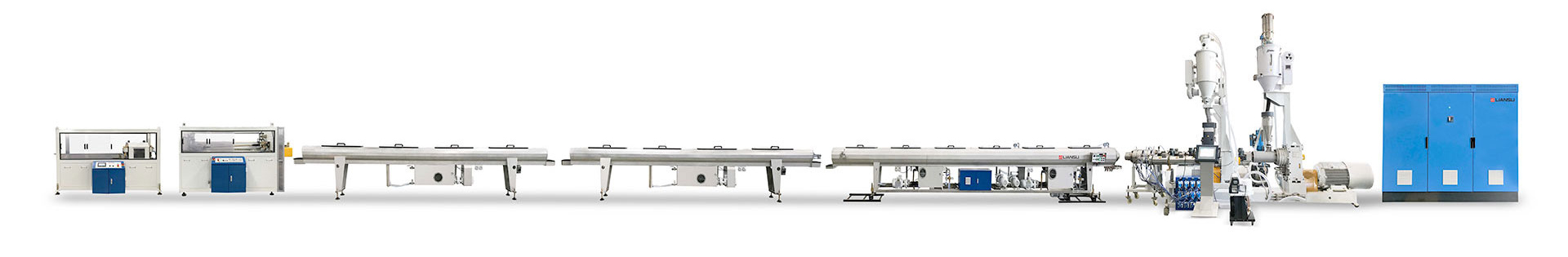

110mm HDPE Three Layer Pipe Production Line

Ø16-Ø250

PIPE RANGE(mm)

25

MAX HAULING SPEED(m/min)

1-3 Layer

CO-EXTRUSION

600

MAX OUTPUT(kg/h)

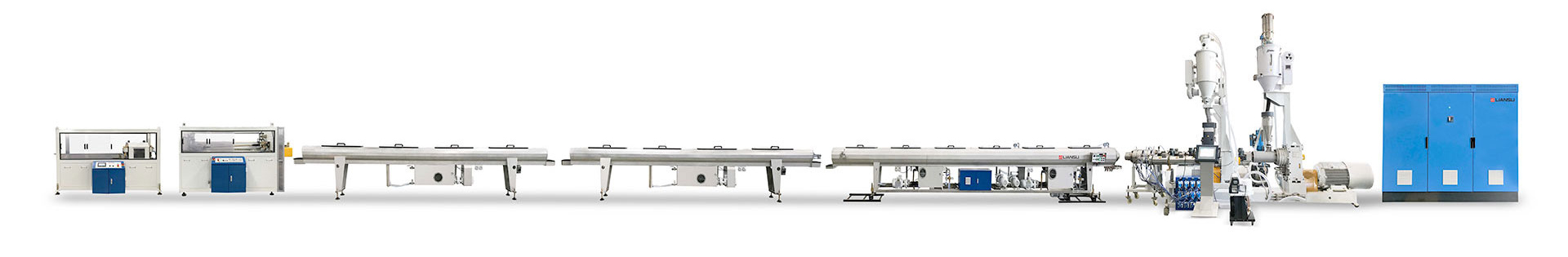

110mm HDPE Three Layer Pipe Production Line

Ø16-Ø250

PIPE RANGE(mm)

25

MAX HAULING SPEED(m/min)

1-3 Layer

CO-EXTRUSION

600

MAX OUTPUT(kg/h)

Product Advantage

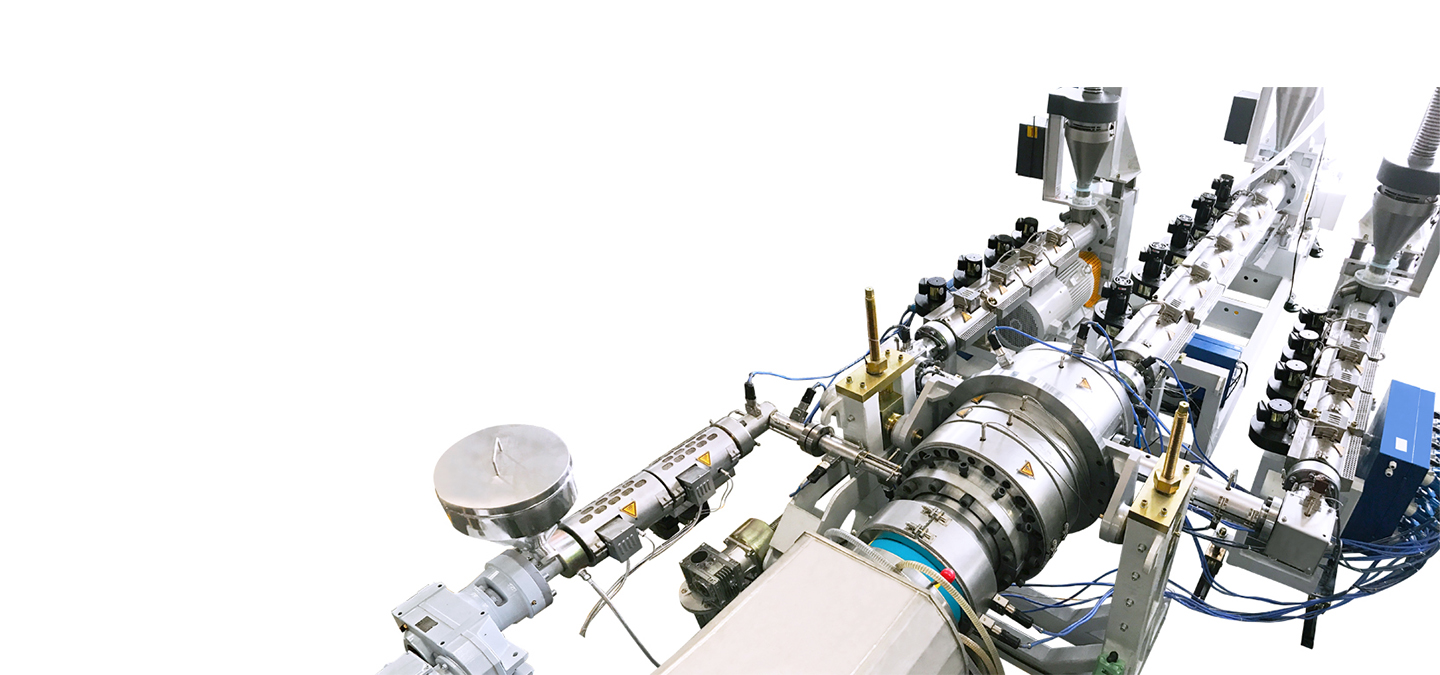

The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

The die body adopts independent spiral mechanism of each layer to ensure the uniformity, and the exhaust mechanism ensures the stable melt temperature under high production and reduces the cooling length.

The hauling adopts servo control to ensure stable production in large speed range.

Equipped with online straight pipe, coil automatic packing mechanism, efficient and labour saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

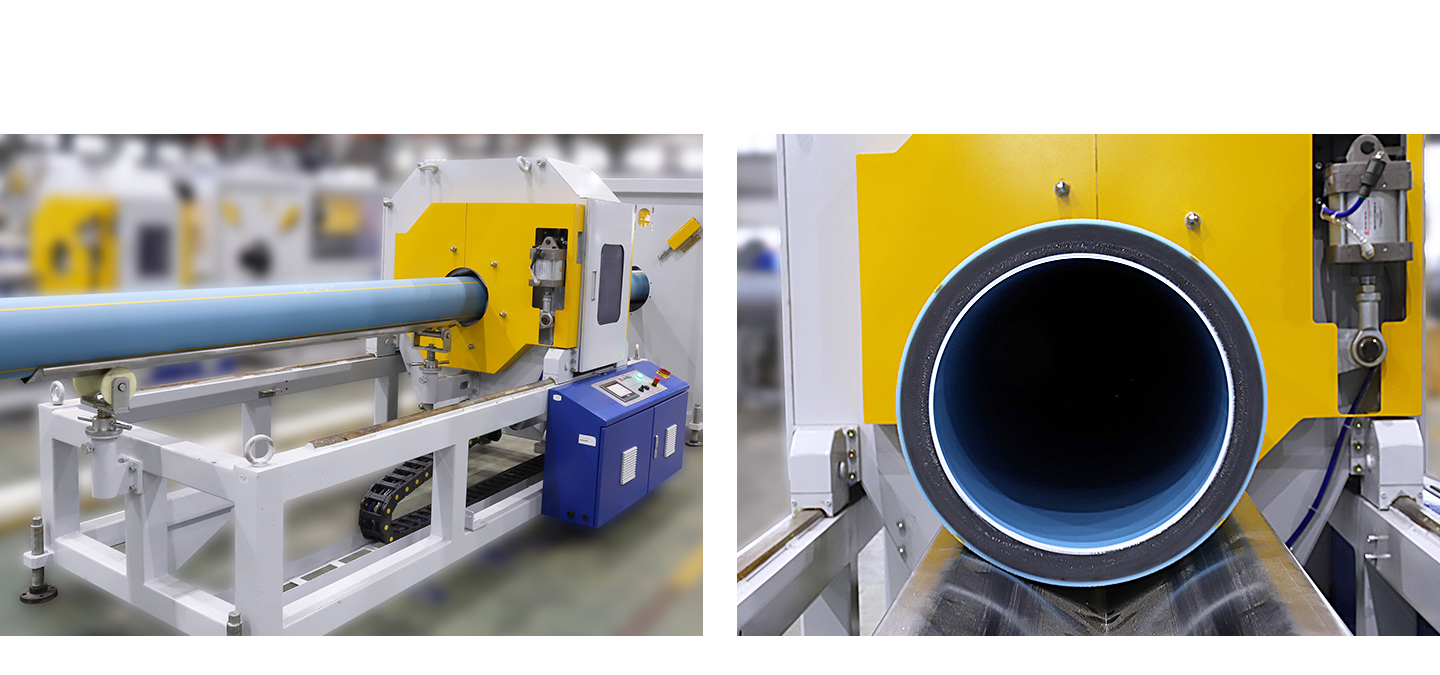

Adopt swarfless cutting mechanism, clear and accurate fixed length, beautiful incision.

The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

The die body adopts independent spiral mechanism of each layer to ensure the uniformity, and the exhaust mechanism ensures the stable melt temperature under high production and reduces the cooling length.

The hauling adopts servo control to ensure stable production in large speed range.

Equipped with online straight pipe, coil automatic packing mechanism, efficient and labour saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

Adopt swarfless cutting mechanism, clear and accurate fixed length, beautiful incision.

Extruder

Mould Design

Mould Design

Vacuum Tank

Vacuum Tank

Haul-off Unit

Cutter

Cutter

Technical Data

* Test and accept based on Liansu standard formula

Sample