Column pipe is a key component in the drilling borewell. It connects the submersible pump to the borewell, enabling water to be extracted from the ground. It is widely used in agricultural irrigation, urban water supply and industrial water treatment.

The pipe is connected with thread end , Liansu can provide online adjustment of pipe thickness to ensure the strength of the pipe thread end. Hereunder we will introduce the PVC pipe extrusion line for borewell submersible pumps. The equipment can on-line flexible control the pipe thickness, with a wide range of pipe diameter and thickness.

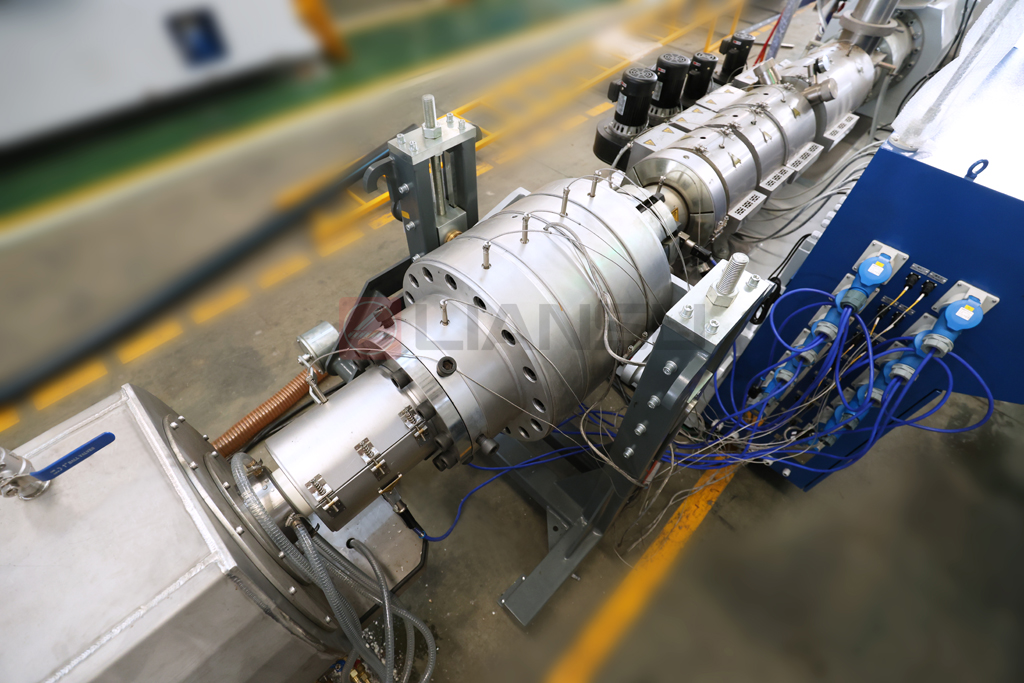

LSP-250 PVC Column Pipe Extrusion Line

Size range:Ø63 —Ø250mmCapacity:450 kg/h

Applicaiton: for borewell submersible pumps

Conical twin-screw extruder match with Mconvey Loss-In-Weight Feeder which is a brand of LlANSU , it can effectively control the weight of pipe, and avoid the material flushing & anti-bridging during material feeding to barrel , ensuring production stability and product quality. Pipe head adopts double compression structure, which not only enhances the pipe performance, but also flexibly meets the need of different process requirements through variable flow channel volume.

The vacuum tank adopts vacuum negative pressure closed-loop control to ensure constant production vacuum degree, improving energy saving and production efficiency.

Four-caterpillar haul-off unit has a wide range of traction speed control and adopts servo control to ensure stable pipe traction and synchronous transportation.

Planetary cutting machine can flexibly control the cutting thickness with wide range. The production line is also equipped with double-heating socketing machine, which can flexibly meet the production needs of online or offline U-shaped and straight socketing.

Video: https://youtu.be/jNHLxxnlL38?si=QuOnF57VmaWyc8VI