Equipment sudden failure disrupts production schedule?

Energy consumption consumed the profits?

but there is no way to trace the source?

Quality inspection relies on manual labor?

fluctuation of quality rate difficult to control?

Production process not transparent?

customer orders unexpected delayed?

....

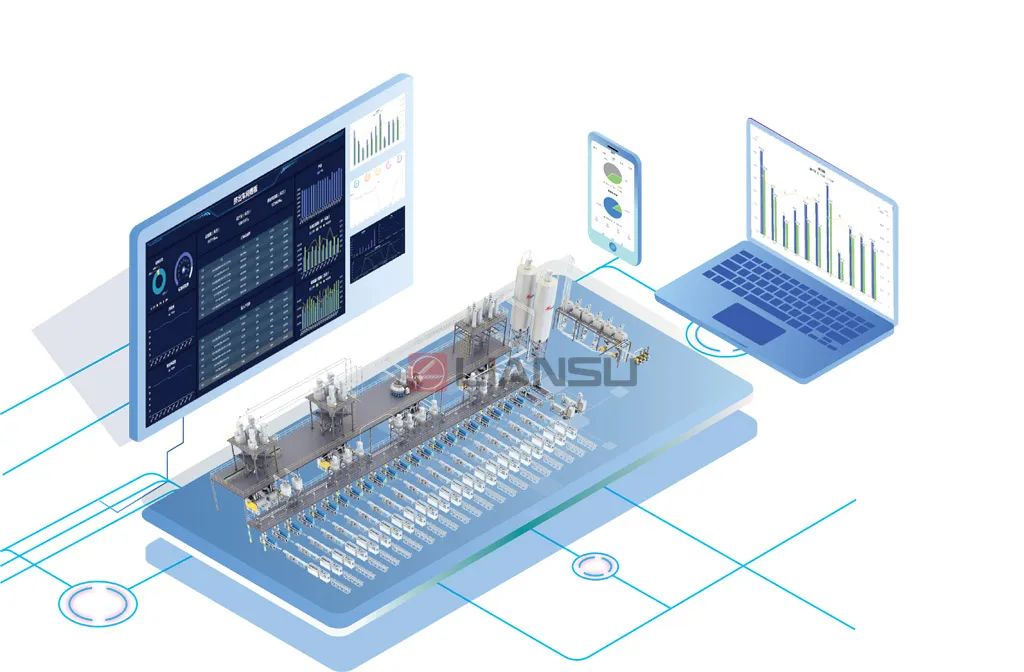

Liansu IoT data collection and analysis system

—— Let equipment can "talk"

- Real-time monitoring: 24-hour monitoring of equipment operation, simultaneous viewing of production data on mobile phones/computers, making management transparent and efficient.

- Intelligent early warning: Analyze the health status of equipment, predict potential failures, push maintenance reminders, and reduce unplanned downtime.

- Efficiency optimization: One-click archiving of the optimal process parameters for each batch of production, forming an enterprise process optimization database, and improving product quality stability.

- Green energy saving: Accurately identify high-energy consumption links, provide data support for energy saving and carbon reduction, and reduce production costs.

Liansu IoT system seamlessly connects plastic extrusion production lines,feeding systems and auxiliary equipment, and uses data to drive decisions, helping you achieve full-link upgrades from production to management.

See you at Chinaplas 2025 booth 8F45 to explore more info!

86 Read