2025-11-03

2025-11-03

26

26

LIANSU PVC High-Output Pelletizing Line delivers a capacity of 2.5 tons per hour, efficiently meeting high-volume production demands and significantly boosting per-unit productivity. Pelletizing line covers entired processing from raw material conveying,dosing and mixing to extruder and pelletizing,finished product storage and packaging. LIANSU high productivity Pelletizing line achieve stable, and low-consumption production goals.

High-Efficiency Extrusion System for PVC compound

Equipped with LSE-128/225 conical twin-screw extruder, its screw configuration is optimized for various PVC compound formulations, ensuring efficient plastification and uniform mixing. This guarantees excellent material flow and extrusion stability. The system is driven by permanent magnet servo motor, providing stable and efficient power with a specific energy consumption as low as 0.06–0.08 kWh/kg and a daily output of up to 60 tons. An optional in-line loss-in-weight feeder enables precise material dosing and real-time control, facilitating flexible color changes during operation while enhancing production stability and product consistency.

Innovative Pelletizing System: Dust-Free, Quiet, Maintenance-Free

LIANSU 's hot-face pelletizing system features patented spiral cooling technology with a dual internal and external cooling channel design,ensuring high throughput. our proprietary enclosed spiral water-cooled conveying system is fully sealed, dust-free, quiet, and maintenance-free. It effectively minimizes dust and odor emissions while reducing failure rates and downtime.

LIANSU spiral cooler adopt a single large-diameter cooling spiral structure where the material remains completely isolated from direct water contact. The spiral operates at an extremely low speed, extending the heat exchange time between the material and cooling water.This approach not only guarantees exceptional cooling efficiency but also significantly enhances equipment longevity (virtually maintenance-free). Crucially, it greatly reduces the risk of pellets being crushed by the spiral, improving product quality while minimizing dust generation and supporting energy-saving and environmental goals.

Automated Packing System: Labor-Saving and Efficient

To meet the packing needs of medium to high-capacity production lines, the system can be optionally equipped with an automatic big bag packing machine.This enables automated pellet loading and inline weighing, substantially reducing labor intensity while improving packing efficiency and product consistency.

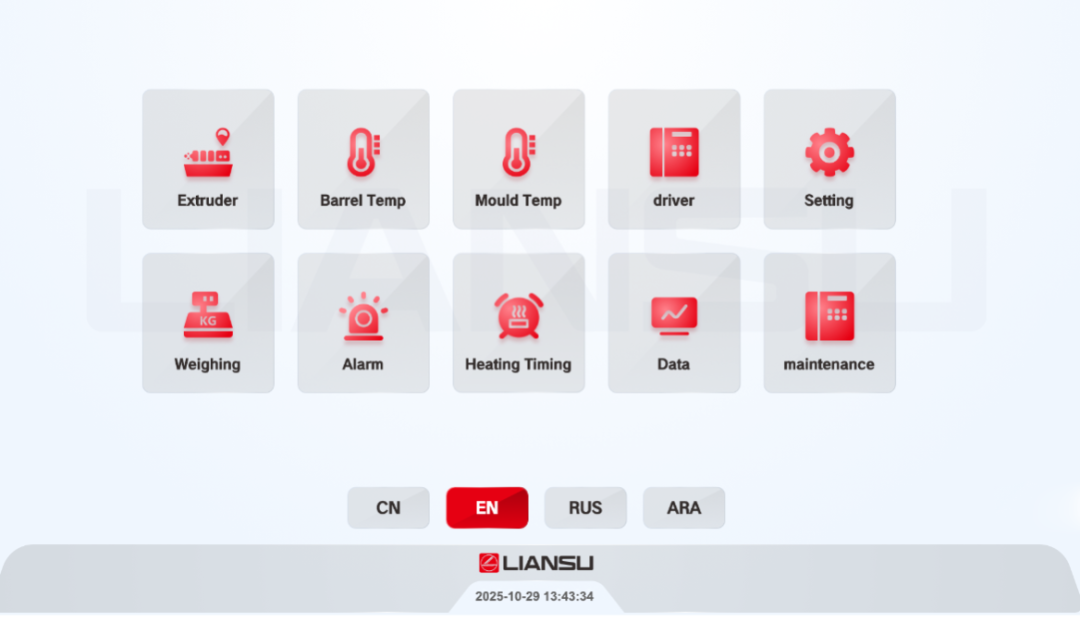

Intelligent Management

The entire line can be optionally configured with the Flexcon+ flexible control system, supporting parameter presets, data tracking, and remote monitoring for simplified management and maintenance. Mconvey also offers customized layout and functional options based on specific customer site conditions, ensuring solutions align with actual production requirements.

More info, please contact: + 86 - 133 9277 5773