2026-01-16

2026-01-16

176

176

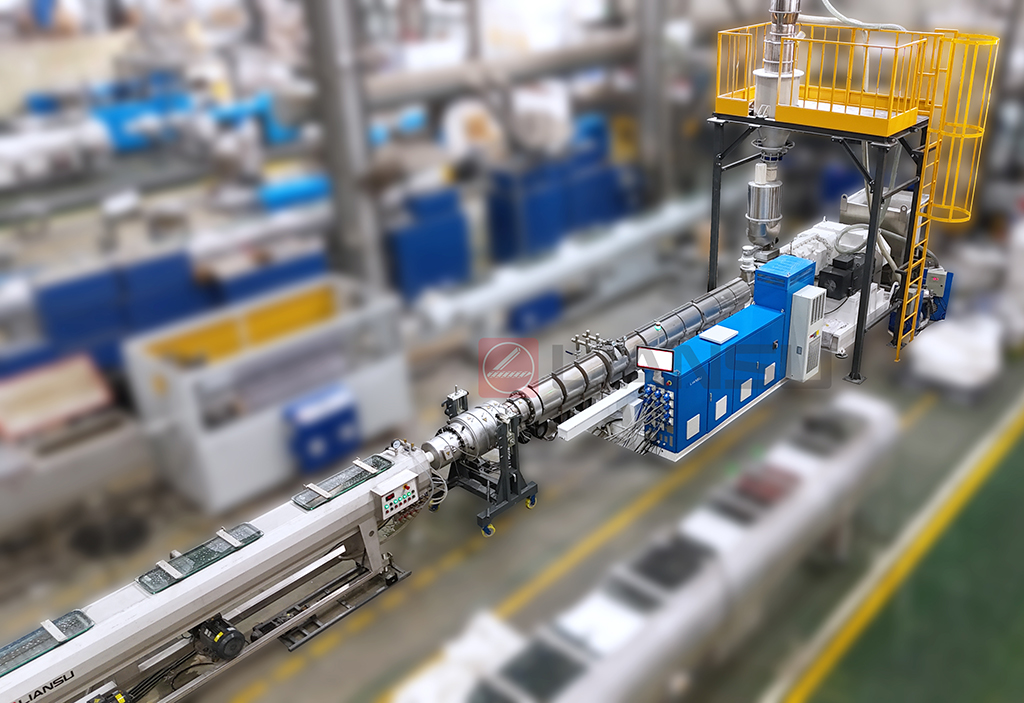

"Improving efficiency and reducing costs" has always been the main objective of plastic pipe manufacturers. LIANSU's high-speed PVC pipe extrusion lines, with its high output and stable performance, provides the industry with an efficient and reliable solution. This issue we will introduces model of LSP-160 PVC pipe extrusion line, which integrates high output, stability, and automation to meet the needs of manufacturers for large-scale production, helping companies achieve the best balance between efficiency and cost.

Technical Specifications

Applicable Pipe Diameter: Ø75—Ø160mm

Production Capacity: 1500 kg/h

Production Speed: 25 m/min

Core Advantages: High-speed and stability, precise temperature control, automated integration

Highlights

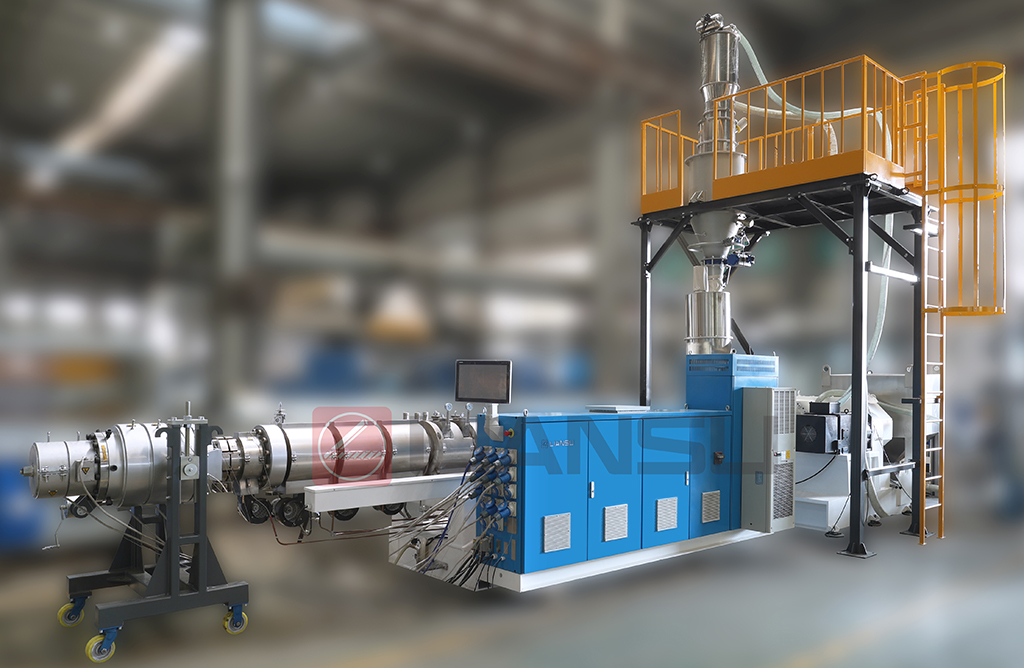

High-Efficiency Plasticization&Stable Extrusion

Adopt 36 L/D Parallel Twin-screw Extruder with a segmented, counter-rotating screw design. Variable screw pitch combinations adapt to material conditions, enhancing material mixing uniformity and plasticizing effects. Combined with an efficient venting structure, ensures the stable melt temperature, and stable, high output extrusion.

Upstream of extrusion, equipped with a high-speed compound mixer and online loss-in-weight feeder which are independently developed by Mconvey. The high-speed compound mixer enables rapid material mixing and drying, cooling and blending process effectively prevents material agglomeration, ensuring material stable feeding. The online loss-in-weight feeder controls the pipe weight per meter and incorporates anti-surge and anti-bridging designs, enabling precise online material proportioning and significantly improving production efficiency and finished product consistency.

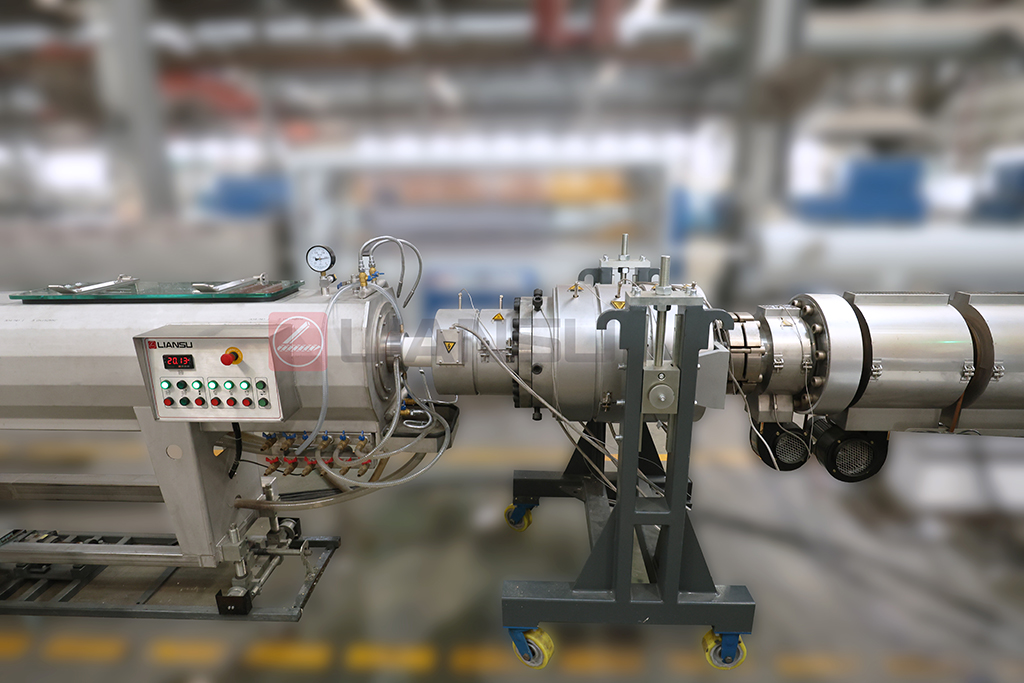

Fast forming & Cooling System

Pipe head adopts a proven bracket structure. with optimized flow channels, ensuring uniform melt distribution, improving pipe forming accuracy and surface finish.

Vacuum cooling system is equiped with a water-ring cooling system and high-precision filtration. Integrated with automatic water level and temperature automatic control, it achieves rapid and uniform cooling, guaranteeing pipe dimensional stability.

Smart Haul-off & Cutting System

Utilizes servo linkage control technology, ensuring precise synchronization between haul-off and cutting. haul-off speed ratio is adjustable over a wide range to adapt to different pipe diameter requirements. The cutting section employs an integrated swarfless cutting and dust-free chamfering structure. Even at high speeds, cutting precision is maintained, reducing manual intervention and comprehensively enhancing the automation level and operational stability of the entire line.

For more information, please contact: 13392775773 (WeChat ID is the same).