2025-10-24

2025-10-24

332

332

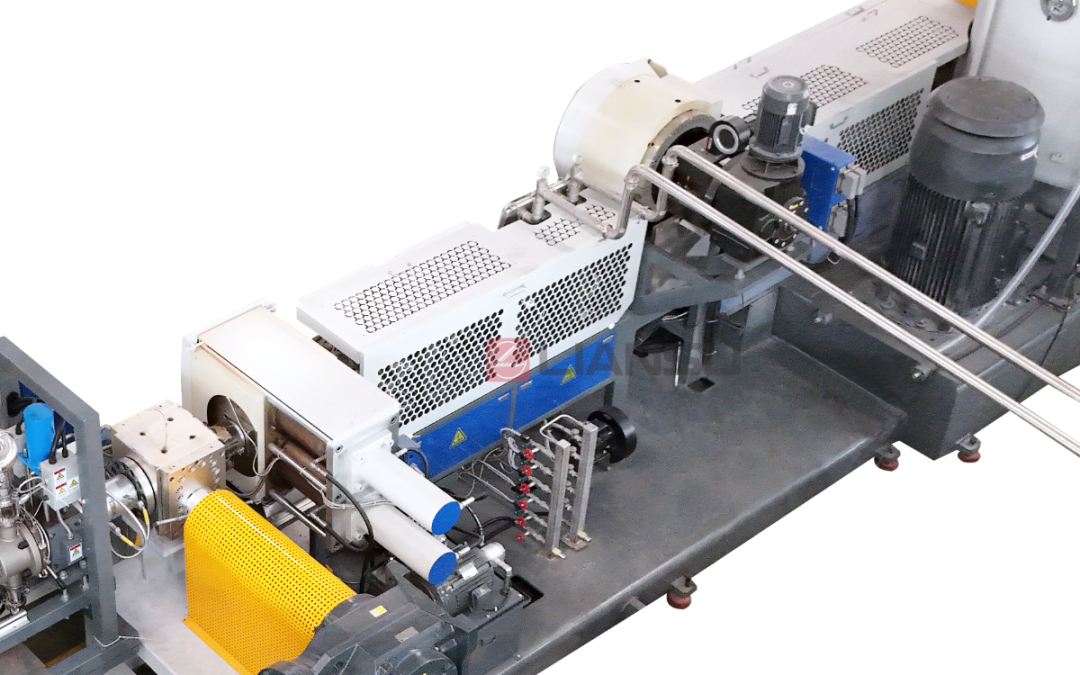

Liansu Mconvey LSHX-150H Double-Filter High-Speed Pelletizing Line, specifically developed for PE film recycling, combines high efficiency with energy savings, delivering an output of 700 kg/h. Complete line processing pre-crushed, washed, dewatered, and dried PE films, enabling efficient continuous operation from feeding to pelletizing. It provides customers with a stable, high-quality recycled pellet solution. The process flow includes: Conveying & Loading → Crushing & Feeding → Extrusion & Filtration → Underwater Pelletizing → Drying → Finished Pellets. Each step is seamlessly integrated, suitable for recycling waste films or plastic bags into pellets.

Solution Configuration

Conveyor Loading, Crushing & Feeding

Recycled films/plastic bags are further crushed in the crushing and feeding stage, then uniformly fed into the extruder to ensure homogeneous melt and high-efficiency production.

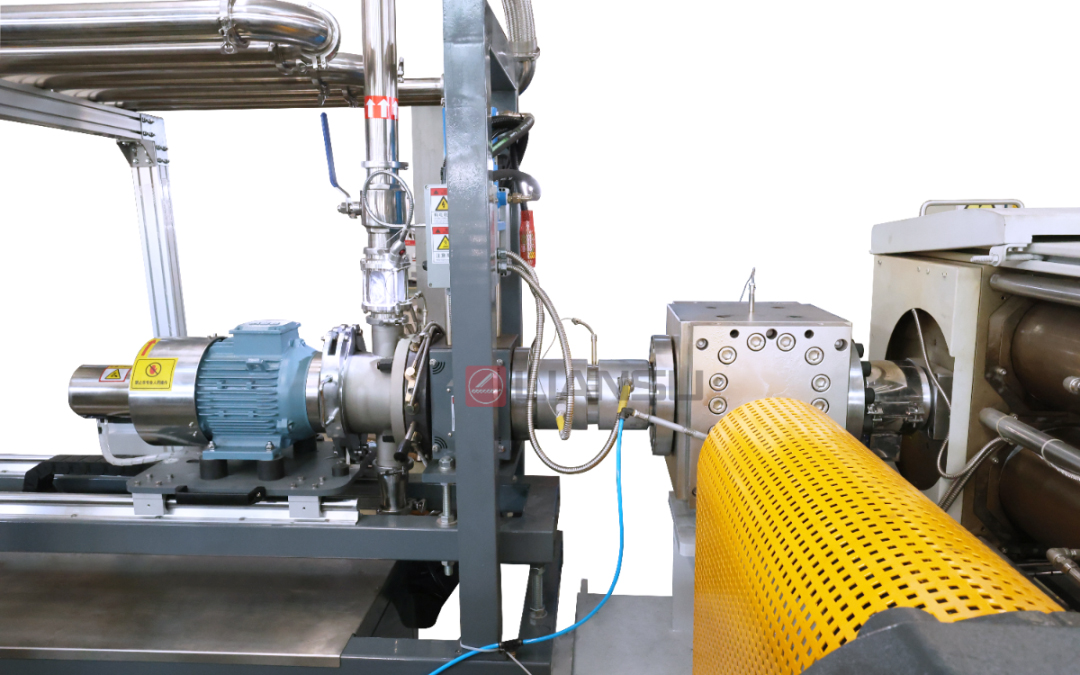

Extrusion & Filtration

Utilizes the LSHX-150H single-screw extruder for material extrusion, plasticization, and filtration. Integrated with a melt laser filter, it enables fully automatic filtration and residue discharge without the need for screen changes. Laser-precision filter pores and a dedicated scraper efficiently remove impurities, maintain stable melt pressure, and ensure uniform, pure pellet quality. This reduces material loss and enables continuous, efficient recycling production.

Underwater Pelletizing

The melt is rapidly cooled underwater and cut into uniform pellets, effectively preventing agglomeration and ensuring pellet quality and appearance.

Drying

The formed pellets pass through a vibrating screen to remove impurities and off-spec pellets. A dryer then quickly removes moisture, ensuring dry surfaces and good flowability, resulting in uniformly shaped, stable-quality recycled pellets.

High output, low energy consumption, fully automatic filtration & residue discharge, stable and durable – making recycling pellet production more efficient and intelligent.

More info, please contact:

+86-18028101014.