2025-09-19

2025-09-19

586

586

LIANSU offers high-speed aluminum composite plastic pipe line reach 20 meter per min. With overlap welding way, optimized downstream structure, improved complete line automatic and reliable production, less waste and stable pipe quality.

Extrusion line Specification

Pipe range: Ø16-Ø32mm

Production Line Speed: 20m/min

Stable and efficient co-extrusion production

Extrusion line is equipped with two single-screw extruders for extrusion of inner and external plastic layers. Precise temperature control system and screw design ensure uniform plasticization and stable flow for high-speed production.

The pipe head adopts a precision flow channel design to efficiently laminate the inner and outer plastic layers with the aluminum layer, ensuring uniform wall thickness, high concentricity, and resistance to delamination. Ultrasonic welding unit further strengthens the aluminum-plastic bond. The modular design supports rapid switching between multiple pipe diameters, maintaining dimensional accuracy and structural stability even during high-speed production.

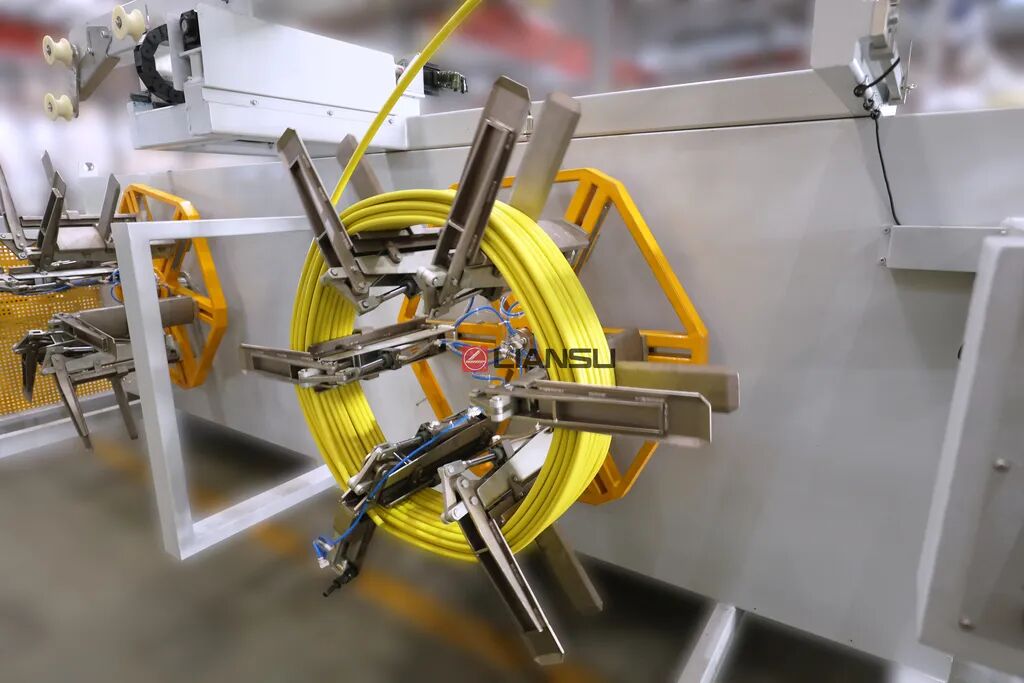

Automation equipment with efficient coordination

In addition, the entire line is well-equipped. The aluminum sheet discharge unit, connection unit and storage box ensure continuous and stable supply of aluminum sheet. Aluminum sheet pre-forming unit achieves precise coating. Cooling water tank and haul off unit ensure the pipe shaped and uniform wall thickness. Flying knife cutter and double-station coiler complete high-speed cutting and neat coiling. The entire process is automated, efficient, coordinated, stable and reliable.

More info, please contact: +86-18028101014.