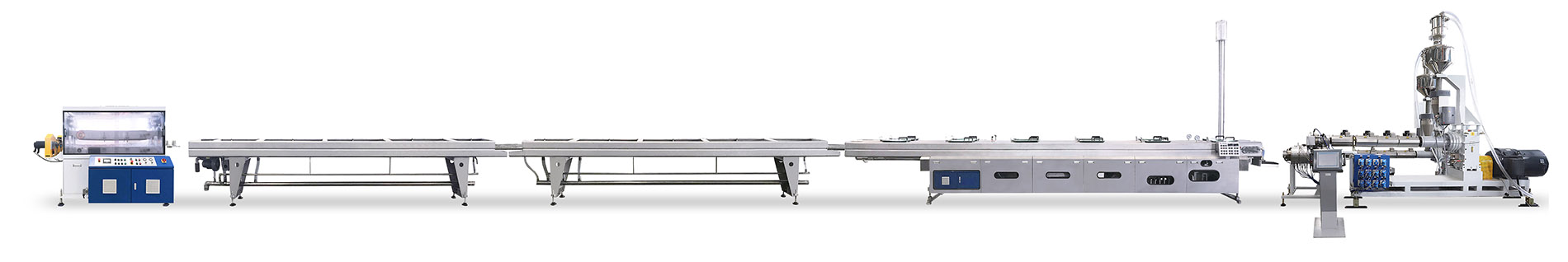

PPR Pipe Production Line

Ø16-Ø160

PIPE RANGE(mm)

7.5-25

MAX HAULING SPEED(m/min)

53

LINE LENGTH(m)

200-450

MAX OUTPUT(kg/h)

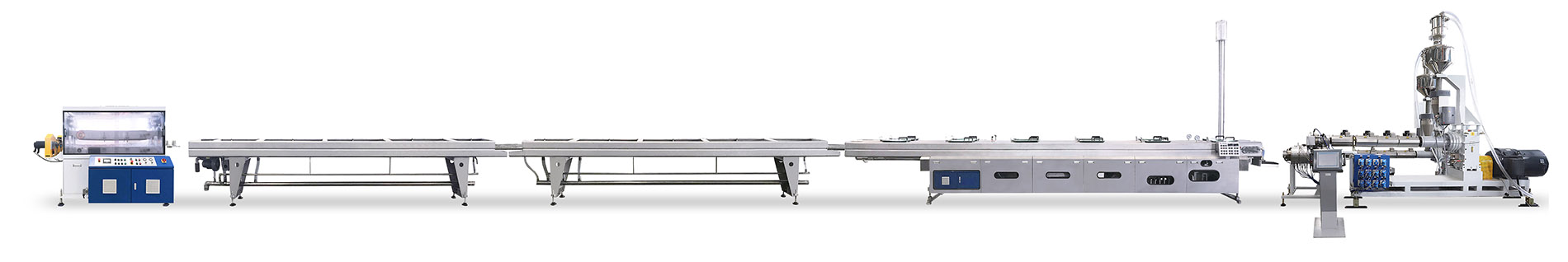

PPR Pipe Production Line

Ø16-Ø160

PIPE RANGE(mm)

7.5-25

MAX HAULING SPEED(m/min)

53

LINE LENGTH(m)

200-450

MAX OUTPUT(kg/h)

Product Advantage

The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

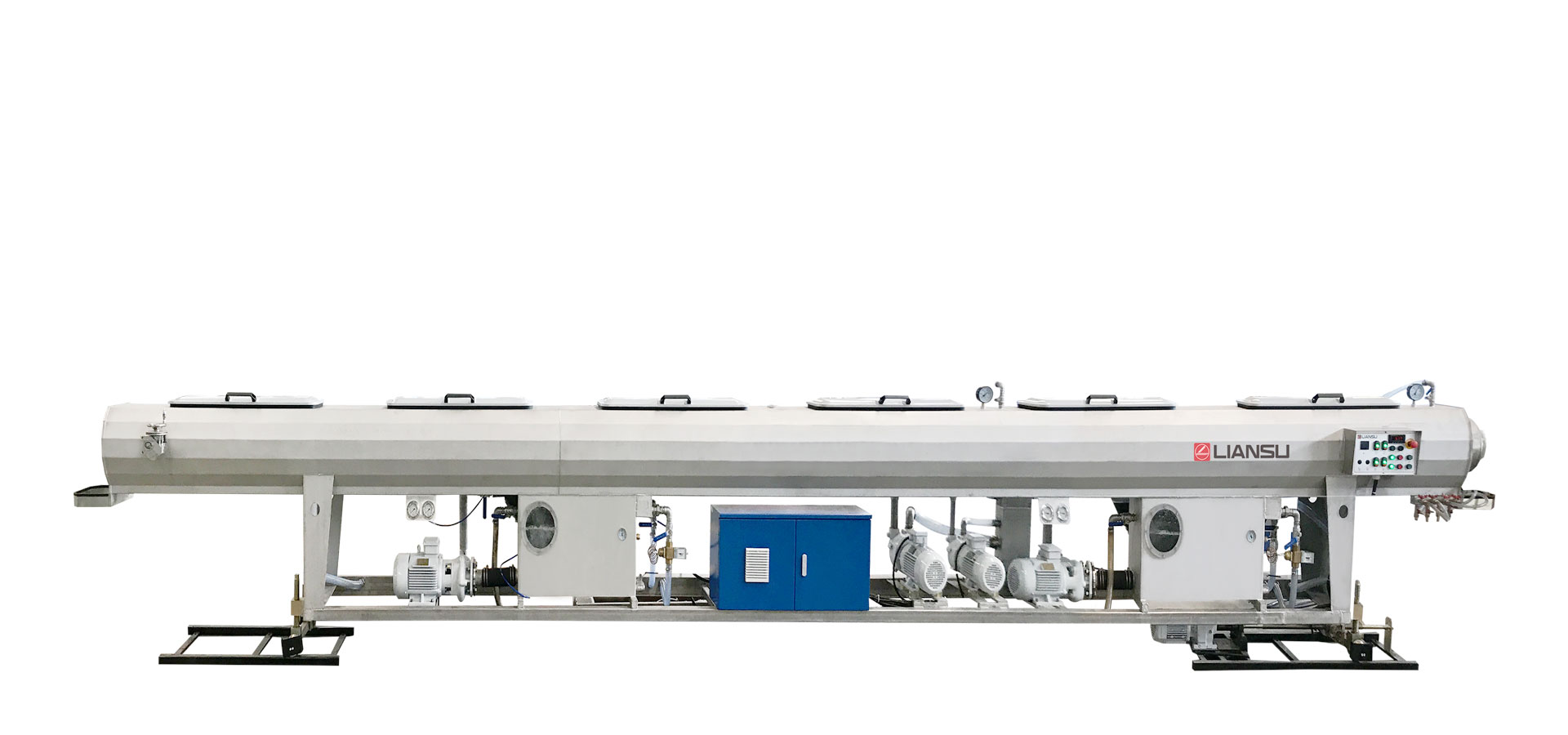

Vacuum adopts frequency conversion closed-loop control, energy-saving and stable.

The hauling adopts servo control to ensure stable production in large speed range.

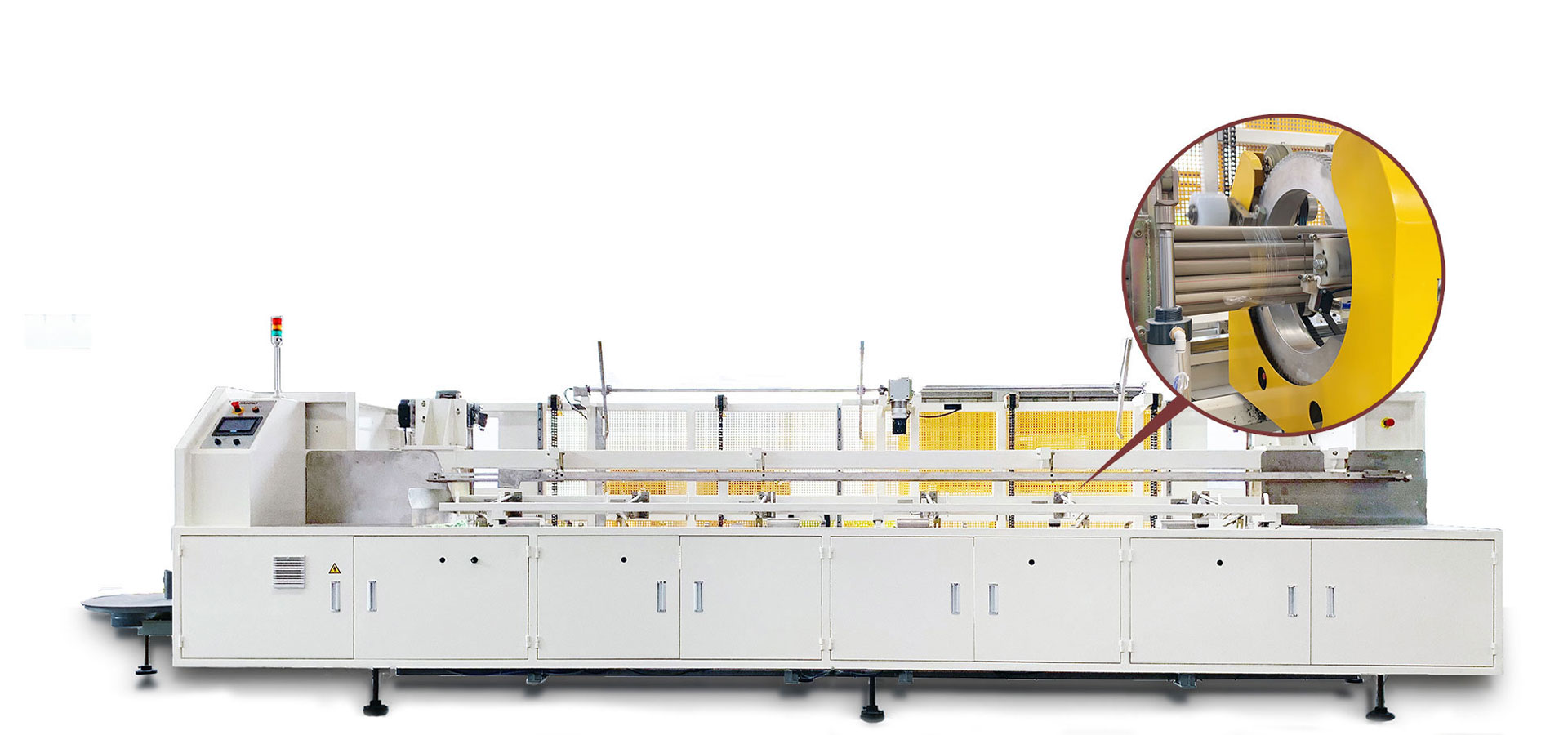

Equipped with on-line straight pipe, coil automatic packing mechanism, efficient and labour saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

The extruder adopts large L/D ratio screw and special permanent magnet synchronous servo motor for extruder to realize high production and energy saving.

Vacuum adopts frequency conversion closed-loop control, energy-saving and stable.

The hauling adopts servo control to ensure stable production in large speed range.

Equipped with on-line straight pipe, coil automatic packing mechanism, efficient and labour saving.

Production data acquisition and analysis system can be selected to realize transparent production management.

Extruder

Mould Design

Vacuum Tank

Vacuum Tank

Haul-off Unit

Haul-off Unit

Cutter

Online Automatic Packaging Device

Online Automatic Packaging Device

Technical Data

* Test and accept based on Liansu standard formula

Sample