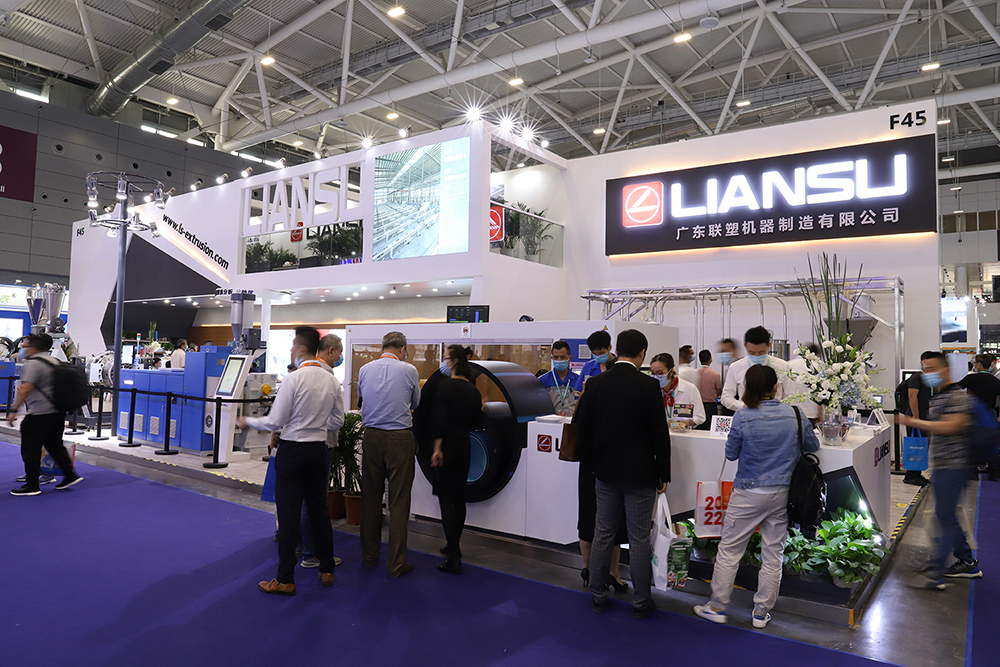

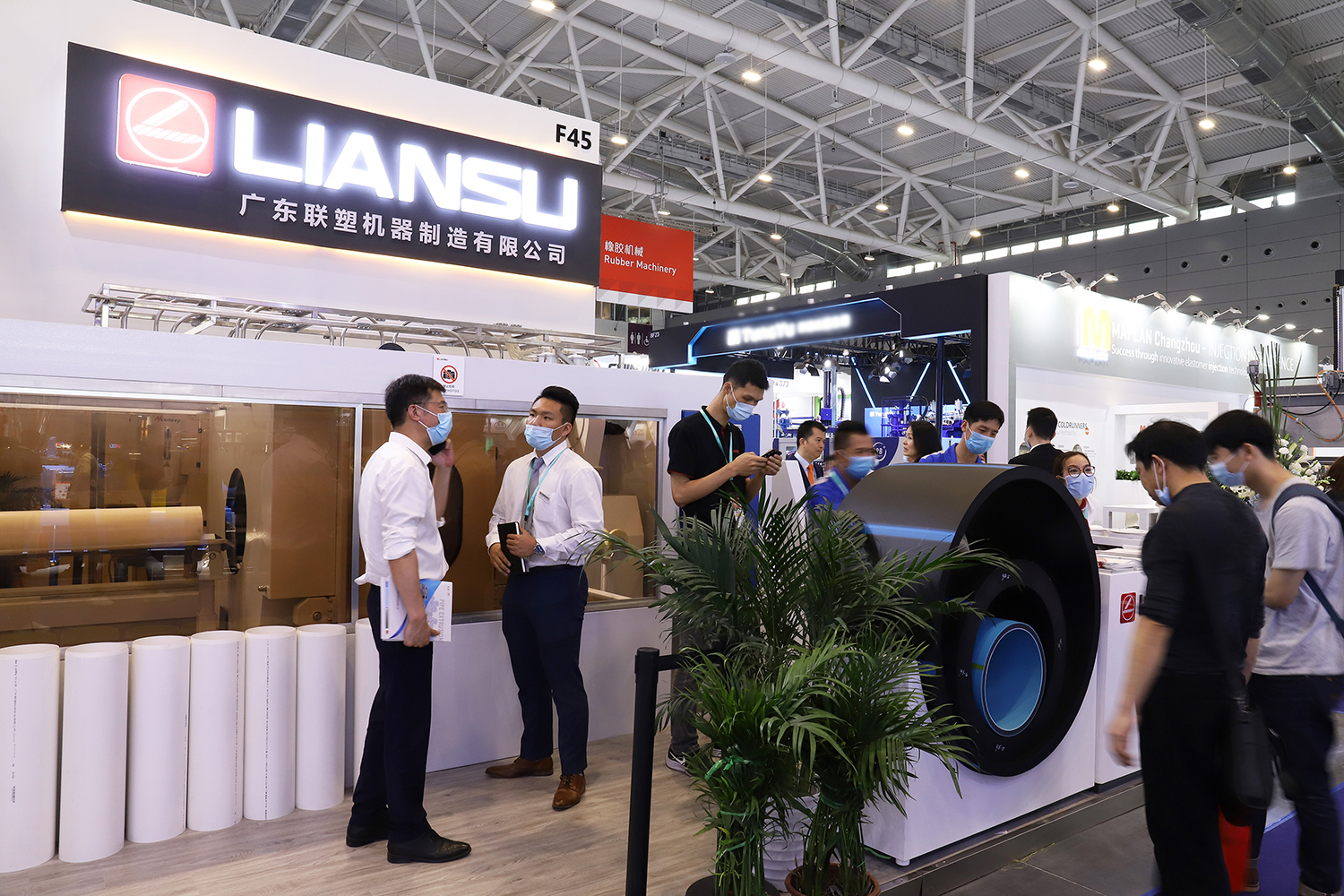

CHINAPLAST arrived as promised, Liansu Machinery is committed to developing "Green Production" and "Digital Manufacturing" in the plastic extrusion industry.We brought Extrusion Equipment , Energy Saving Exhibition Area,Automation Exhibition Area and Digital Exhibition Area for you.Next,let me introduce the first two days of the exhibition:

Extrusion equipment exhibition area_ PVC/HDPE plastic pipe extrusion equipment technology

◆It is suitable for parallel twin-screw extruder of PVC national standard pipe and single screw extruder of HDPE pipe.Both of them have the features of large L/D ratio and high energy saving. The screw design is specially optimized according to the material characteristics of plastic pipes to ensure the product quality and high output at the same time.

◆ The three-layer pipe mould developed for multi-layer HDPE pipe adopts spiral basket structure, which is easy to maintain and ensures the accurate thickness of each layer.

◆ The modular design of PVC pipe mould is suitable for a wide range of specifications, economical, and can quickly change the thickness of specifications.

DEMO” Energy saving exhibition area_DEMO for plastic extrusion processing energy saving "

Demonstrate the PK effect of super high efficiency permanent magnet synchronous motor for extruder and the latest cutting-edge reluctance synchronous motor and AC asynchronous motor,and plastic pipe negative pressure vacuum shaping closed-loop rapid adjustment, energy saving and noise reduction effect,caterpillar synchronization effect of the permanent magnet synchronous drive scheme of "one pull more" in pipe hauling.

DEMO Automation exhibition area_Plastic automatic centralized feeding system DEMO

◆ Dynamic demonstration of dense phase conveying of PVC powder:Has the features of high conveying efficiency (solid gas ratio > 15:1),low air flow speed, flexible pipeline layout and long conveying distance(can reach 200m).

◆ PE/PPR particle feeding system is set up on site, which is composed of weighing color masterbatch mixer, split vacuum suction machine, weighing color masterbatch mixer, multi-component weighing mixer, dryer and other commonly used plastic auxiliary machinery. At the same time of on-the-spot display of high-quality plastic auxiliary machinery with centralized supply,dynamically demonstrates material conveying and mixing process in circulation.

◆ For all kinds of PVC, PE, PPR materials, solving the problems in the process of conveying, storage, weighing,dosing and mixing, and provide the best solution and overall project planning, and finally build a turnkey project customized according to customer demand.

Digital exhibition area_“FLEXCON+integrated equipment control+Flexible industrial control system based on data interconnection”

The embedded "double system" specially developed for plastic extrusion production line is PLC control system+information PC system. The two systems run in one terminal at the same time to realize the high integration of program control, data acquisition and analysis!

◆ Graphical operation interface, easy to understand the extrusion line equipment operation, can control the whole line operation.

◆ Based on Windows 10 system development, seamless integration of information data acquisition, analysis system, convenient management.

◆Embedded dual system--PLC control system+information PC system runs in a terminal.

◆ 17” impact resistant touch screen.

For more product information, welcome to exhibition hall 8 F45!